Metal Paint Cans Manufacturer

Metal Paint Can

Shining Packaging’s metal paint cans deliver superior packaging for art, construction, automotive, and industrial applications. Crafted from high-quality tin-plated steel, they offer unmatched protection against air, light, and moisture, ensuring product integrity and extended shelf life. Outperforming plastic with excellent heat resistance, these fully recyclable cans—over 40% of U.S. steel is recycled—range from 118ml to 6L. Equipped with secure, resealable lids and customizable printing, they blend brand appeal with robust functionality.

Capacity

118ml – 6L

Height

60-280mm

Thickness

0.23-0.28mm

Inner coating

Epoxy resin

MOQ

20,000 PCS

Cap

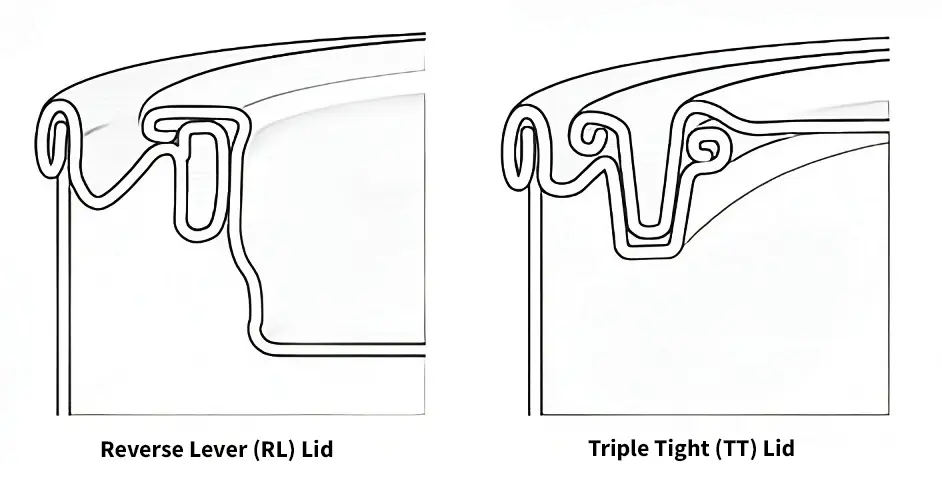

Reverse Lever (RL) lid , Triple tight lid

Diameter

65mm, 76mm, 85mm, 105mm, 108mm, 152mm, 165mm, 167mm, 178mm

Printing

offset printing

Metal Paint Can Size

| Capacity | Thickness | Diameter | Height | Shape | Handle | Closed |

|---|---|---|---|---|---|---|

| 118 ml | 0.23-0.25 mm | 65 mm | 60 mm | Round | Metal / Plastic | Lever Lid |

| 250 ml | 0.23-0.25 mm | 76 mm | 70 mm | Round | Metal / Plastic | Lever Lid |

| 370 ml | 0.23-0.25 mm | 85 mm | 85 mm | Round | Metal / Plastic | Lever Lid |

| 1 pint | 0.23-0.25 mm | 85 mm | 100 mm | Round | Metal / Plastic | Lever Lid |

| 500 ml | 0.23-0.25 mm | 85 mm | 105 mm | Round | Metal / Plastic | Lever Lid |

| 1 quart | 0.23-0.25 mm | 105 mm | 125 mm | Round | Metal / Plastic | Lever Lid |

| 1 liter | 0.23-0.25 mm | 108 mm | 130 mm | Round | Metal / Plastic | Lever Lid |

| 2 liter | 0.25-0.28 mm | 167 mm | 130 mm | Round | Metal / Plastic | Lever Lid |

| 3 liter | 0.25-0.28 mm | 152 mm | 133 mm | Round | Metal / Plastic | Lever Lid |

| 1 gallon | 0.25-0.28 mm | 165 mm | 190 mm | Round | Metal / Plastic | Lever Lid |

| 4 liter | 0.25-0.28 mm | 165 mm | 205 mm | Round | Metal / Plastic | Lever Lid |

| 5 liter | 0.25-0.28 mm | 178 mm | 230 mm | Round | Metal / Plastic | Lever Lid |

| 6 liter | 0.25-0.28 mm | 178 mm | 280 mm | Round | Metal / Plastic | Lever Lid |

Key Features

Detail of Metal Paint Can

—01

Size Options

- Capacity Range: From 118ml to 6L, including standard sizes like 500ml, 1 quart, 1L, 1 gallon (3.78L), and 5L.

- Customization: Tailor diameter, height, and capacity to meet specific needs.

- Material: Premium tin-plated steel ensures durability and corrosion resistance.

- Compatibility: Designed to integrate seamlessly with existing filling lines and mixers.

—02

Lid Options

- Reverse Lever (RL) Lid: Closes inside the ring, available in raised or low panel styles, ideal for sizes up to 1L with superior airtightness.

- Triple Tight (TT) Lid: Fits within the ring with a three-point seal, perfect for color mixing systems, commonly used for 500ml and 750ml cans.

- Tamper-Evident Design: Ensures product security and prevents unauthorized access.

- Color Customization: Lids available in custom colors to align with brand identity.

- Secure Sealing: 100% leak-proof with resealable closure systems.

—03

Printing Capabilities

- 360-Degree Offset Printing: Eliminates labels for striking shelf appeal.

- Coating Options: Transparent coating for a natural metallic sheen or vibrant white for bold colors.

- Finish Choices: Glossy or matte finishes to match brand aesthetics.

- Printing Technologies: Includes silk screen, offset lithography, cameo, flexographic, and digital printing for versatile design options.

—04

Interior Coating

- High-Performance Coating: Epoxy resin lining ensures corrosion resistance and compatibility with diverse products.

- Complete Isolation: Fully separates contents from the can material for maximum protection.

- Custom Finishes: Available in transparent, gold, or white to enhance product presentation.

—05

Accessories

- Bails (Handles): Metal or plastic, fixed on sides or top for easy carrying.

- Can Clips: Metal or plastic clips secure lids to prevent drying or leaks.

- Armloks (Locking Rings): Movable metal wire rings enhance sealing and portability.

- Funnel Accessory: Supports precise pouring for professional applications.

Metal Paint Can Manufacturer

As a leading metal paint can manufacturer, we operate fully automated production lines delivering 100–150 premium cans per minute. Our streamlined process—featuring precision forming, epoxy lining, high-definition printing (CMYK offset/digital), and secure closure integration (RL/TT lids)—ensures chemically resistant, stackable containers. Crafted from electroplated tinplate for total light/oxygen barrier protection, every ISO 9001 & UN-certified can guarantees durability, resealability, and vibrant brand impact. Ideal for paints, coatings, lubricants, and adhesives, we engineer sustainable, retail-ready packaging that performs flawlessly worldwide.

Related Products

Have Questions?

Frequently Asked Questions

What materials are used to make metal paint cans?

Metal paint cans are crafted from high-quality materials like electro-plated tinplate (tin-coated steel), steel, and aluminum. Tinplate offers durability and corrosion resistance, steel provides strength for rough handling, and aluminum ensures lightness and resistance to acidic paints, making these cans versatile for various applications.

What are the key advantages of using metal paint cans?

Metal paint cans provide total barrier protection against light, gas, and oxygen, preserving paint quality. They are fire-resistant, durable in harsh conditions, and tamper-proof. Their resealable design, recyclability, stackability, and lack of need for secondary packaging make them convenient, sustainable, and cost-effective for businesses.

In which industries are metal paint cans commonly used?

From artists to construction professionals, metal paint cans are ideal for storing acrylic and oil-based paints, wall and floor coatings, automotive primers, and rust prevention coatings. They are also suitable for adhesives, mastics, and lubricants, ensuring reliable storage across industries.

What sizes do metal paint cans come in?

Metal paint cans are available in a wide range of sizes, from 100ml for small projects to 6 liters for industrial use. Detailed specifications, including dimensions, can be found in our comprehensive product catalog, ensuring you find the perfect size for your needs.

What printing options are available for metal paint cans?

We offer advanced printing methods such as silk screen, offset lithography, flexographic, and digital printing for vibrant, high-quality branding. Internal coatings in transparent, gold, or white finishes are also available to prevent reactions between the paint and the metal, ensuring product integrity.

What types of lids are available for metal paint cans?

Our metal paint cans feature Reverse Lever (RL) lids for a tighter airtight seal, ideal for smaller cans, and Triple Tight (TT) lids for easy resealing and high quality, perfect for color mixing systems. Both are suitable for paints and lacquers, ensuring secure storage.

What accessories are used metal paint cans?

Yes, accessories include handles (bails) for easy carrying, available in metal or plastic, and locking rings (Armloks) for enhanced sealing and portability. Can clips are also provided to secure lids, preventing leakage or drying, especially for professional-grade cans.

Are metal paint cans environmentally friendly?

Yes, metal paint cans are made from sustainable, infinitely recyclable materials like steel . Their durability and reusability reduce waste, while their stackable design minimizes storage space, making them an eco-friendly choice for environmentally conscious businesses.

How should I store paint in metal cans to ensure it lasts longer?

Store metal paint cans in a cool, dry place with temperatures between 60°F and 80°F. Always seal the lid tightly after use, using plastic wrap if the lid is crusted. Protect from direct sunlight and extreme temperatures to maintain paint quality over time.

Are metal paint cans safe for storing flammable paints?

Absolutely. Metal paint cans are designed with excellent fire resistance and stability in harsh conditions, making them ideal for storing flammable contents. Their tamper-proof design and robust construction ensure safe storage, even in demanding environments.

How do I open a metal paint can properly?

Use a flathead screwdriver or a paint can opener to gently pry open the lid by inserting the tool under the edge. Be cautious to avoid spills. After use, clean the rim and reseal tightly to prevent drying or contamination.

Can metal paint cans be reused after use?

Yes, metal paint cans can be thoroughly cleaned and reused for storing other liquids or as general containers. Their durability, resealable lids, and stackability make them perfect for multiple uses, promoting sustainability and reducing waste.