Leading Supplier of Bag On Valve System

Why Choose Us

Bag On Valve Manufacturer

At Shining Aluminum Packaging, we excel in the design, development, production, and supply of aerosol cans and dispensing packaging solutions. Our extensive product lineup features aerosol cans, valves, actuators, BOV systems, and various accessories. We cater to both the technical and aesthetic needs of our clients, enabling them to distinguish themselves and thrive in a competitive market.

- 30-500ml

- FDA & LFGB

- Clean Workshop

- Automatic Production Line

- 24-Hour BOV Leak Test

- 300,000 Pcs/Day

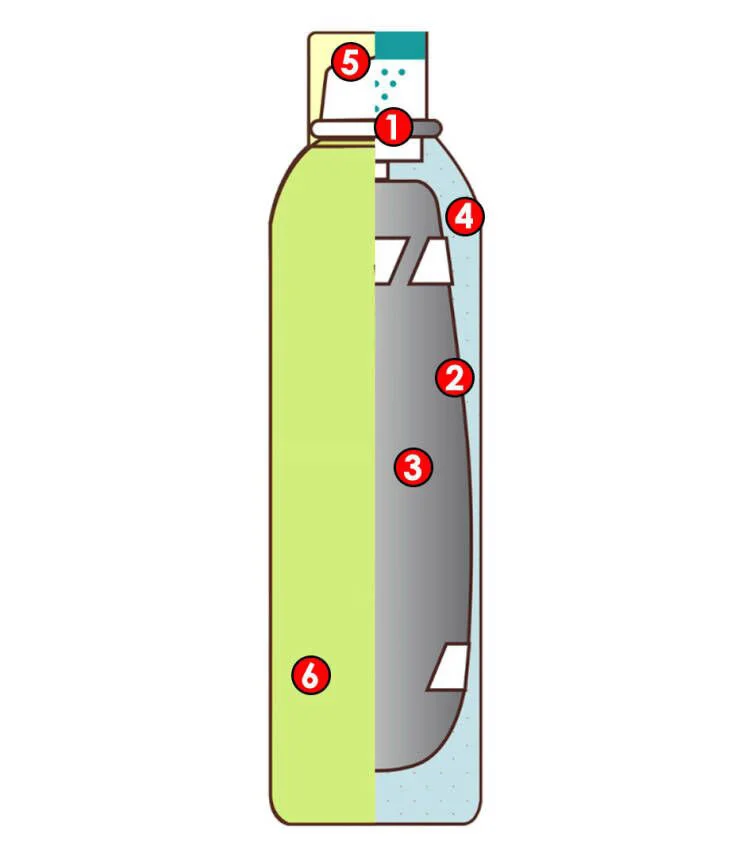

Bag On Valve Technology

- 1. Valve: Bag-on-valve (B.O.V.) systems are available with both female and male valves.

- 2. B.O.V.: These systems feature FDA and LFGB-approved multi-layer laminated pouches, available in a large range of sizes from 1 fl. oz. to 14 fl. oz.

- 3. Product: B.O.V. systems are suitable for liquids and most viscous products like creams and lotions, across a variety of application areas. They are optimized for oxygen-sensitive and sterile products. Note that dry powders are not compatible with B.O.V. systems.

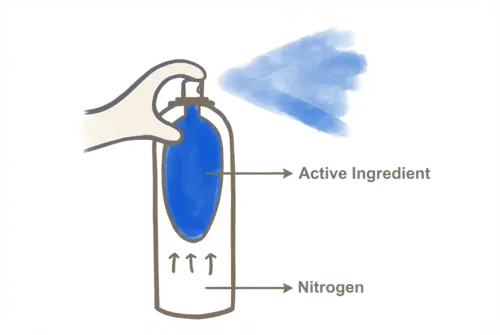

- 4. Propellant: Air or nitrogen should be used—never liquid gases.

- 5. Actuator & Cap: large range of standard actuators are available depending on product demands. Some actuators, such as the twist lock actuator, do not require a cap. Standard overcaps can be used with many types of containers and actuators.

- 6. Aerosol Can: Standard DOT pressure-rated containers made from aluminium, steel, and tinplate can be used. A wide variety of shaped containers are compatible.

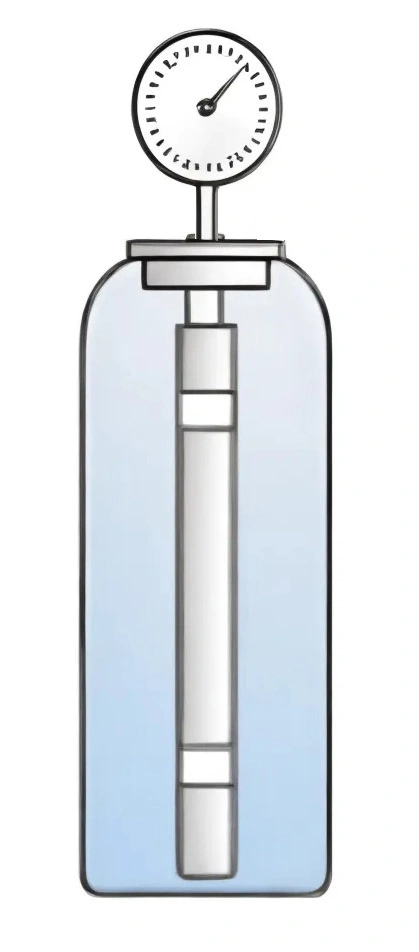

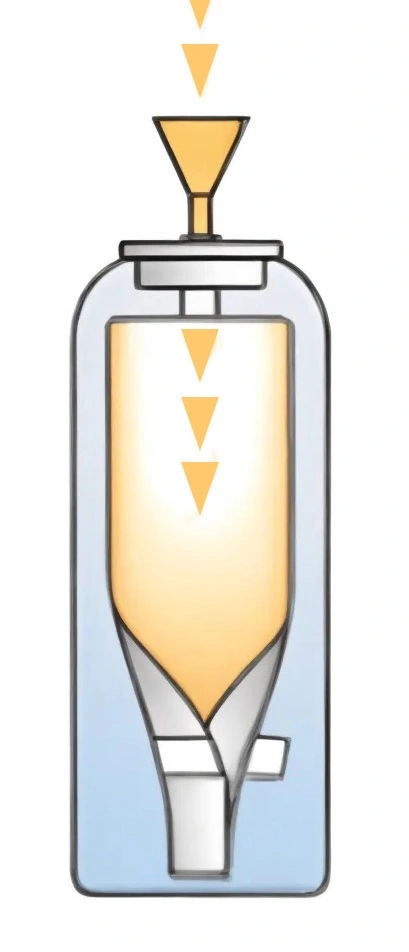

Bag On Valve Aerosol Filling Process

Bag On Valve aerosol Can Size

| Product Number | Spray Can Size (mm) | BOV Filling Capacity (ml) | BOV Size (mm) |

| NV25.4E-30 | Φ35×90 | 30 | 60x65x25 |

| NV25.4E-50 | Φ35×110 | 50 | 90x65x25 |

| NV25.4E-80 | Φ40×120 | 80 | 100x80x25 |

| NV25.4E-100 | Φ45×125 | 100 | 100x90x25 |

| NV25.4E-150 | Φ45×150 | 125 | 125x90x25 |

| NV25.4E-150 | Φ50×155 | 150 | 125x90x25 |

| NV25.4E-200 | Φ53×180 | 200 | 145x100x32 |

| NV25.4E-300 | Φ59×215 | 300 | 180x100x32 |

| NV25.4E-300-2 | Φ66×180 | 300 | 150x115x35 |

| NV25.4E-400 | Φ66×215 | 400 | 190x115x35 |

| NV25.4E-500 | Φ66×240 | 500 | 213x115x35 |

bag on valve spray can

Bag On Valve vs. Aerosol

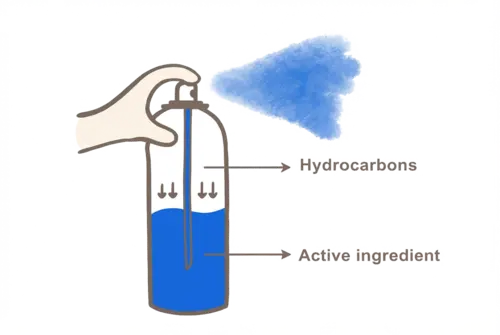

Aerosol Can

Bag On Valve

| Feature | Traditional Aerosol | Bag-on-Valve (BOV) |

|---|---|---|

| Tightness / Sealing | Poor sealing, no bag to protect the body packaging | Multiple protective material bodies formed by valves, four-layer vacuum bags |

| Product Purity | The propellants and ingredients are mixed, the ingredient is not pure enough | The propellants and ingredients are separated, no compatibility problems |

| Atomization | Poor atomization | Continuous nano-atomization |

| Convenience | Have sediment, shake it before use, and press several times during use | No sediment, spray anytime, no need to press many times |

| Use Angle | Can’t upside down | 360° |

| Utilization | Have residue, waste | >98% |

| Jet Sound | Hissing sound | Mute |

| Environmental and Safety | The propellant is discharged out of the tank, flammable | The propellant is not discharged out of the can, does not affect the environment, and reduces the flammability of the product |

| Propellants | Hydrocarbons | Nitrogen, Air |

| Price | Cheap | Expensive |

| Fill | Ingredient first, then propellants | Propellants first, then ingredient |