Aerosol Valve Filling Techniques: Methods and Efficiency

When it comes to aerosol valve production, the filling process is a critical step. Aerosol valves must be filled with precision and accuracy to ensure each product performs consistently and safely for end-users. In this article, we’ll explore the main filling methods—UTC, pressure filling, and the gasser shaker method—each offering unique advantages for different applications. Whether you’re new to aerosol valve production or an experienced manufacturer, understanding these techniques can be invaluable in ensuring your product’s quality and reliability.

Common Filling Methods for Aerosol Valves

The three most common aerosol filling techniques are UTC (under-the-cup), pressure filling, and the gasser shaker method. Each of these methods provides unique benefits, and the choice depends on the specific product, propellant, and production goals.

1. UTC (Under-the-Cup) Filling Method

UTC, or Under-the-Cup Filling, is a popular method for filling aerosol valves when high precision is required. This technique involves sealing the valve onto the can before injecting the propellant. The product is first filled into the can, after which the propellant is added through a hole in the valve stem. This method ensures minimal product waste and a clean, consistent fill.

Advantages of UTC: The primary benefit of UTC is that it reduces the chance of contamination, as the product is filled separately from the propellant. Additionally, UTC allows for a controlled fill, ensuring that only the desired amount of propellant is injected.

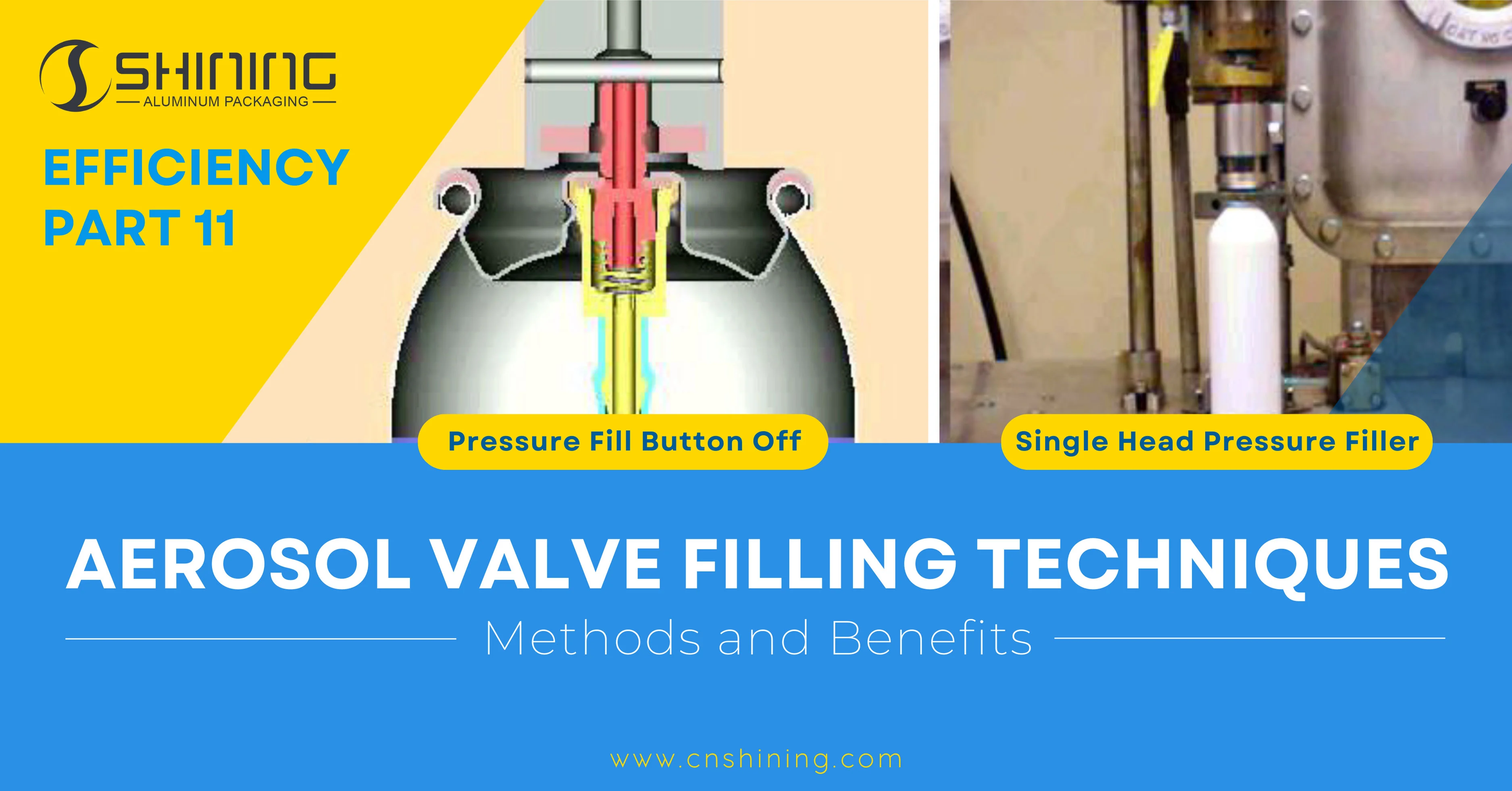

2. Pressure Filling Method

Pressure filling is another effective technique where both the product and the propellant are added through the valve once it’s crimped to the can. In this method, a vacuum is typically used to remove any excess air before filling, enhancing the seal and preserving the product’s quality.

Advantages of Pressure Filling: This method is advantageous for filling cans with high-viscosity products as it enables the use of liquefied gases, which generate a consistent spray over time. It’s also preferred for applications where a strong, steady spray pattern is desired.

3. Gasser Shaker Method

The gasser shaker method is often used for specialized aerosol products. Here, the can is filled and crimped, then subjected to a shaking process to allow the gas to dissolve into the product. This method is especially common for food-grade aerosols, where precise distribution of the propellant within the product is needed to achieve a high-quality spray.

Advantages of Gasser Shaker: By shaking the can, this method ensures that the propellant and product are thoroughly mixed. It’s particularly effective for food and beverage applications where consistency in spray quality and flow is essential.

Integrating Filling Methods with Production Lines

Seamlessly integrating aerosol filling techniques with production lines is key for efficiency. Manufacturers often design production lines to handle multiple filling techniques, allowing for flexibility in production. Automated systems are also commonly employed, enabling precision, reduced labor costs, and improved consistency. Modern production lines often utilize real-time monitoring to detect any potential issues during the filling process, ensuring that each aerosol can is correctly filled and ready for distribution.

For high-demand applications, such as healthcare or personal care products, production lines need to be optimized for speed without compromising quality. Manufacturers increasingly incorporate smart technologies like IoT and AI for predictive maintenance and enhanced operational efficiency.

Quality Assurance in Aerosol Valve Filling

Quality control is an essential aspect of aerosol valve filling, especially for industries with stringent regulatory requirements. Here are some steps manufacturers can take to ensure quality assurance:

- Leak Testing: Each filled can is tested for leaks to avoid product waste and ensure safety.

- Weight Check: Verifying the weight of each filled can is crucial for quality control, ensuring each product has the right amount of contents.

- Spray Pattern Testing: For products where spray quality is paramount, testing the spray pattern helps guarantee consistent user experience.

- Valve Functionality Testing: To ensure the valve opens and closes properly, manufacturers test each unit to confirm functionality.

Many manufacturers invest in automated testing machines, which can quickly assess these parameters and reduce human error. Additionally, real-time data from the production line can be used to adjust parameters on the go, ensuring high-quality output for every can.

10 Common FAQs on Aerosol Valve Filling Techniques

- What is the best filling method for aerosol valves? It depends on the product type. UTC is ideal for clean fills, pressure filling for high-viscosity products, and gasser shaker for even gas distribution.

- How do I choose the right propellant? Consider product viscosity, desired spray pattern, and environmental impact when selecting a propellant.

- How does UTC filling prevent contamination? UTC fills the product first, then the propellant, minimizing contact and contamination risks.

- Is pressure filling suitable for all products? Pressure filling is versatile but works best for products with liquefied gas propellants for consistent spray.

- What quality checks are important after filling? Leak tests, weight checks, and spray pattern verification are essential for quality assurance.

- Why is gasser shaker used for food-grade aerosols? It ensures uniform propellant distribution within the product, important for consistent spray in food-grade applications.

- Can filling methods be automated? Yes, many manufacturers use automated systems to enhance efficiency and accuracy in filling.

- How do I ensure environmental compliance? Choose eco-friendly propellants and follow waste management protocols for compliance.

- What’s the importance of spray pattern testing? It ensures the product delivers the desired coverage, crucial for applications like personal care products.

- How do automated systems improve filling efficiency? They reduce labor costs, minimize errors, and enable high-speed production with consistent quality.

Ready to Learn More?

At our factory, we specialize in advanced aerosol valve manufacturing techniques, ensuring each product is filled with precision and quality. Visit our product page for more information or contact us directly to discuss your aerosol valve needs. Our team of experts is here to guide you through every step, from choosing the right valve to quality assurance in filling.

For further insights on aerosol valve filling methods, visit this article on Wikipedia to deepen your understanding of aerosol spray technology.

Related Articles

- Uncovering Part 1: What Are Aerosol Valves and Why Are They Essential?

- Exploring Part 2: A Brief History of Aerosol Valves – From Invention to Modern Technology

- Detailed Look Part 3: How Do Aerosol Valves Work? A Breakdown of Their Mechanics

- Highlight Part 4: Top Benefits of Aerosol Systems Across Various Industries

- In-Depth Part 5: A Closer Look at Key Components of Aerosol Valves

- Analysis Part 6: Types of Propellants in Aerosol Valves and Choosing the Right Fit

- Discovery Part 7: Exploring Different Types of Aerosol Valves and Their Applications

- Step-by-Step Part 8: Understanding Aerosol Valve Operations in Detail

- Insight Part 9: Actuators in Aerosol Valves – Types, Functions, and Design

- Key Focus Part 10: The Importance of Crimping in Aerosol Valve Assembly

- Efficiency Part 11: Aerosol Valve Filling Techniques – Methods and Benefits

- Selection Guide Part 12: Choosing the Right Aerosol Valve for Your Product

- Troubleshooting Part 13: Common Issues with Aerosol Valves and How to Solve Them

- Future Trends Part 14: Innovations in Aerosol Valve Technology and Sustainability

- Case Study Part 15: Success Stories in Aerosol Valve Applications Across Industries

- Resource Part 16: Glossary of Key Aerosol Valve Terms and Industry Resources