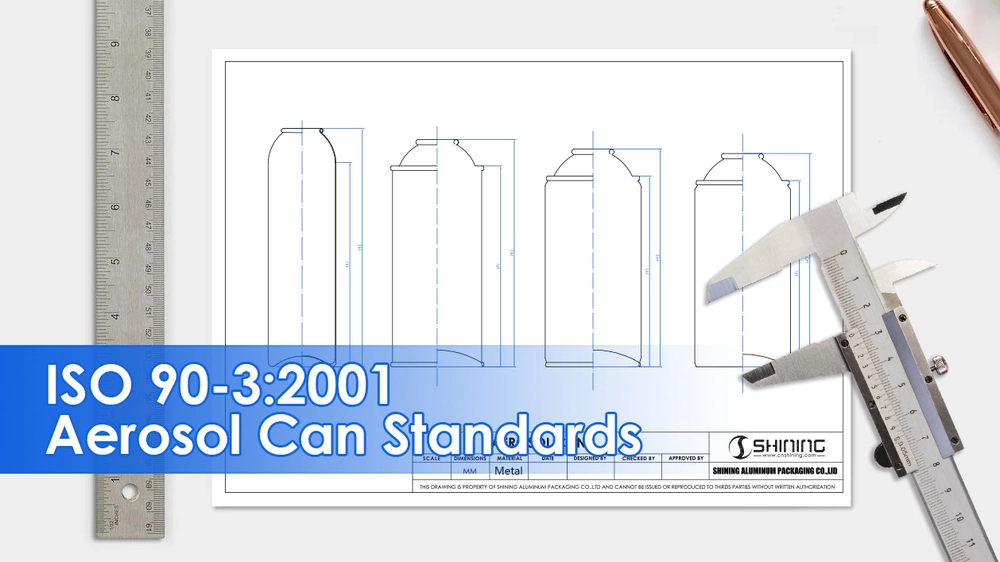

Introduction

ISO 90-3:2001, titled “Light gauge metal containers — Definitions and determination of dimensions and capacities — Part 3: Aerosol cans”, is an essential global standard for manufacturers, engineers, and procurement teams involved in aerosol packaging. It focuses on terminology, dimensional measurements, capacity definitions, and tolerances specifically for metal aerosol containers with wall thicknesses not exceeding 0.49 mm.

1. Scope

This part of ISO 90 defines key physical aspects of aerosol cans—such as diameters, apertures, heights, and shapes—used in industrial packaging. It includes detailed instructions for calculating brimful and gross capacities and recommends an international designation system for consistency across supply chains.

2. Terms and Definitions

2.1 Aerosol Can

A rigid, sealed metal container (≤0.49 mm thick) designed to dispense pressurized content via a valve system.

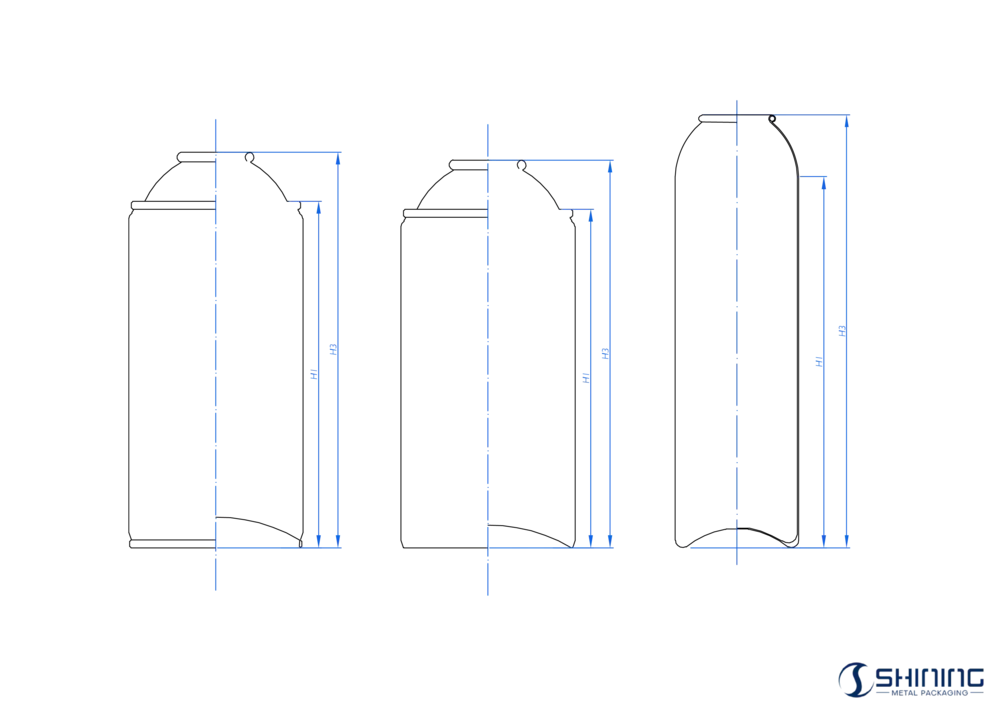

2.2 Heights

- Body Height – Vertical dimension excluding top dome.

- Overall Height – Total height including dome and flange.

2.3 Aperture

A circular opening designed for valve insertion and sealing within a valve cup.

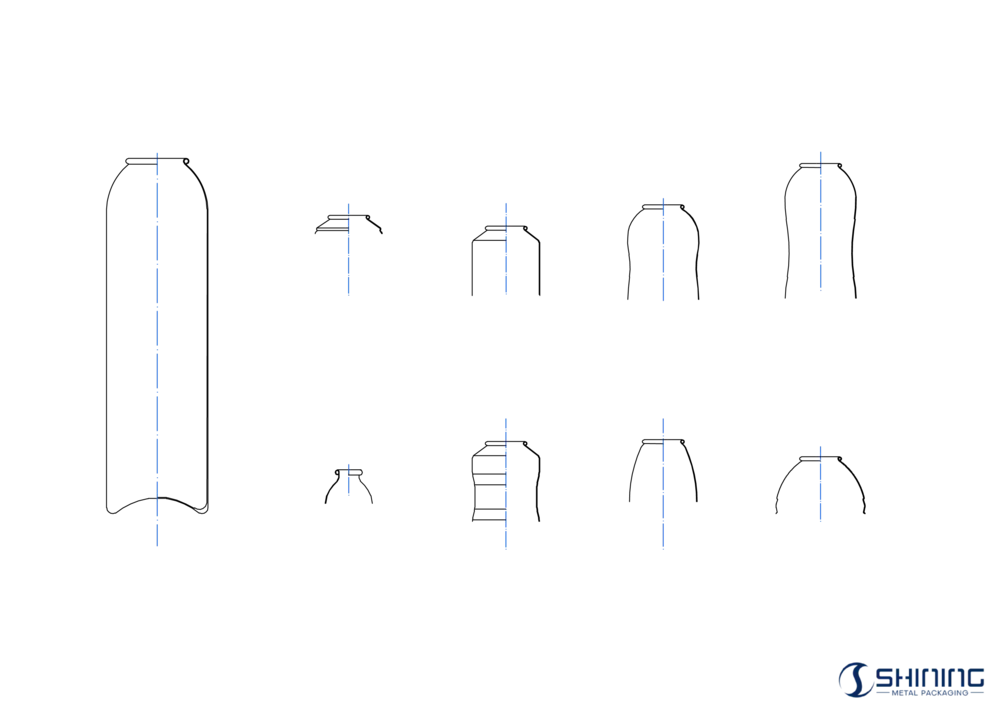

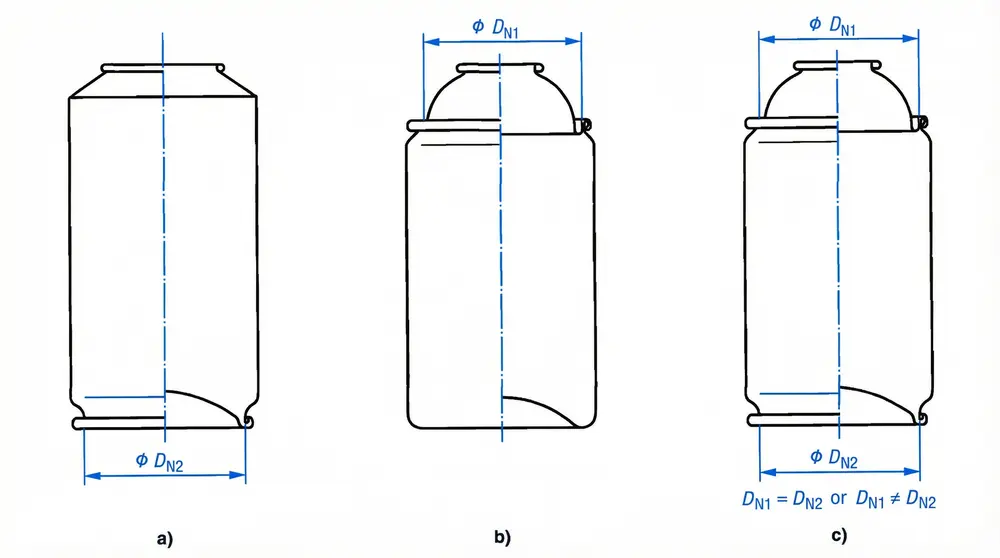

2.4 Construction Types

- Three-piece cans: Body, top, and bottom assembled.

- Two-piece cans: Either an extruded body with a top or a drawn wall-ironed body with bottom and shoulder.

- Monobloc cans: Single-piece with various shoulder styles (e.g., ogival, spherical, flat).

2.5 Shapes

- Straight-sided: Constant diameter throughout body.

- Necked-in: Body reduced at one or both ends.

2.6 Capacities

- Gross lidded capacity (C1): total capacity of a can, fitted with a valve, valve cup and dip tube.

- Brimful capacity (C2): Maximum fill without closure.

3. Determination of Dimensions

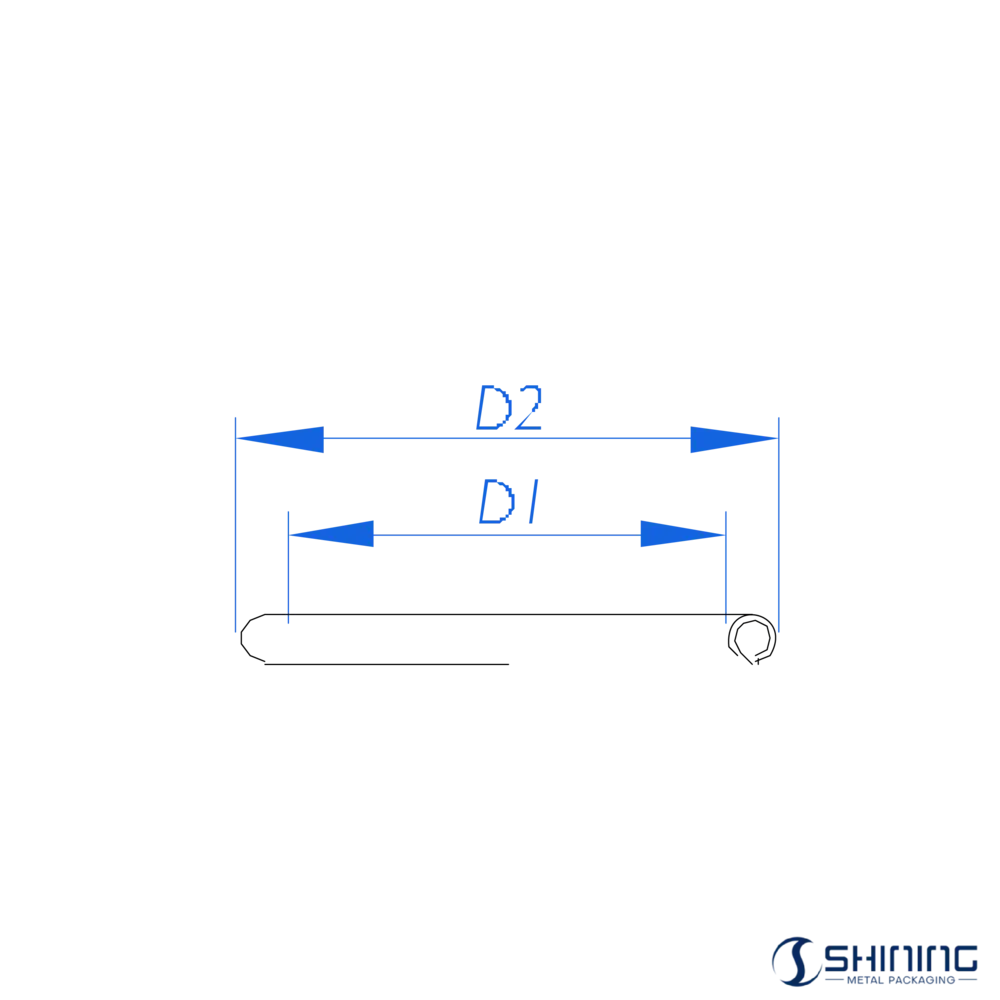

3.1 Diameter

- Internal measured by plug gauge.

- External by vernier caliper.

3.2 Height

Measured using a vernier or digital height gauge. Round to the nearest whole millimeter.

3.3 Nominal Values

Values must be rounded according to rule: if .5 or above, round up; otherwise, round down.

4. Determination of Capacities

4.1 General Procedure

Capacity is determined by weighing filled cans. Correction factors apply based on water temperature.

4.1.1 Temperature Correction Table

| Water temperature °C |

Correction factor F |

|---|---|

| 12 | 1.0005 |

| 14 | 1.0008 |

| 16 | 1.0011 |

| 18 | 1.0014 |

| 20 | 1.0018 |

| 22 | 1.0022 |

| 24 | 1.0027 |

| 26 | 1.0033 |

| 28 | 1.0038 |

| 30 | 1.0044 |

4.2 Brimful Capacity Test

- Weigh empty can with disc (m₀)

- Fill with water, avoid bubbles

- Weigh filled can (m₁)

- Calculate: (m₁ – m₀) × correction factor = C2 (ml)

5. Tolerances on Capacities

Table: Tolerance by Volume

| Capacity (ml) | Allowed Tolerance |

|---|---|

| ≤ 100 | ±4 ml |

| 101–200 | ±6 ml |

| 201–300 | ±8 ml |

| 301–400 | ±10 ml |

| > 400 | ±2.5% |

6. Designation System

Each aerosol can should be internationally identified using three metrics:

- Brimful capacity (C2)

- Nominal diameter (D)

- Overall height (H)

Example: A cylindrical can with 250 ml brimful capacity, 52 mm diameter, and 134 mm height: C2 250 - D52 - H134

7. Annex A – Necked-In Can Top Dimensions

Real-World Applications

- For Manufacturing

Ensures precise engineering tolerances and component compatibility.

- For Filling & Automation

Capacity and diameter tolerances reduce underfill/overflow risks during high-speed filling operations.

- For Procurement

Standard designations simplify international sourcing and QC specifications.

Download the Standard PDF

This document contains the official text of ISO 90-3, which defines terms, dimensional requirements, and methods for determining dimensions and capacities of light gauge metal aerosol cans. It is intended to support standardized container design, dimensional verification, and capacity evaluation for manufacturing, quality assurance, and technical reference purposes.

Frequently Asked Questions (FAQ)

ISO 90-3 is not legally mandatory, but it is the global reference for defining aerosol can dimensions and capacities. Most EN and FEA standards are built on ISO 90-3 terminology and measurement logic, making it functionally unavoidable in practice.

ISO 90-3 provides a common language for capacity, diameter, and height across international suppliers. This significantly reduces specification ambiguity and sourcing risks in multi-region procurement.

Yes. ISO 90-3 applies to all light-gauge metal aerosol cans, including aluminium monobloc containers. Material-specific behaviour is addressed later by EN or FEA standards built on this base.

ISO 90-3 defines how dimensions and capacities are measured and designated. FEA standards refine these definitions for specific systems such as 20 mm or 25.4 mm openings and tooling interfaces.

ISO 90-3 recognizes common shoulder types such as ogival and spherical. However, functional sealing and clinch behaviour are controlled later by EN or FEA standards.

Yes. Water density varies with temperature, directly affecting measured volume. Ignoring correction factors can lead to systematic filling errors, especially for larger containers.

Custom designs are possible, but ISO 90-3 definitions should still be used as the reference framework. This ensures compatibility with filling equipment, testing methods, and downstream standards.

Standard tools include vernier or digital calipers, plug gauges, and calibrated weighing scales. The focus is on repeatable measurement rather than specialized or destructive testing.

At low volumes, small absolute deviations represent large percentage errors. This has a greater impact on filling accuracy, product performance, and regulatory compliance.

Yes. ISO 90-3 forms the technical foundation for EN aerosol container standards. Using ISO 90-3 ensures consistency between global ISO references and regional EN requirements.