Standard Overview

EN 14847 defines the critical dimensional requirements of 25.4 mm (1 inch) aperture tinplate aerosol cans. The standard focuses on the can opening geometry that directly affects valve clinching performance, sealing reliability, and functional safety.

While ISO 90-3 establishes the general dimensional and capacity framework for aerosol cans, EN 14847 goes one step further by specifying the functional interface between the can and the valve system. For this reason, EN 14847 is typically applied together with EN 14848 (valve cups) and ISO 90-3 during product design and procurement.

1.Key Aperture Dimensions and Technical Meaning

25.4 mm Aperture Geometry

The 25.4 mm aperture is a globally adopted interface for aerosol valves. EN 14847 specifies not only the nominal diameter, but also the surrounding dimensional envelope that governs clinch deformation and sealing contact.

Instead of controlling radii and angles directly, the standard relies on measurable functional dimensions such as:

- Contact height

- Inside diameter

- Outside diameter

- Shoulder height

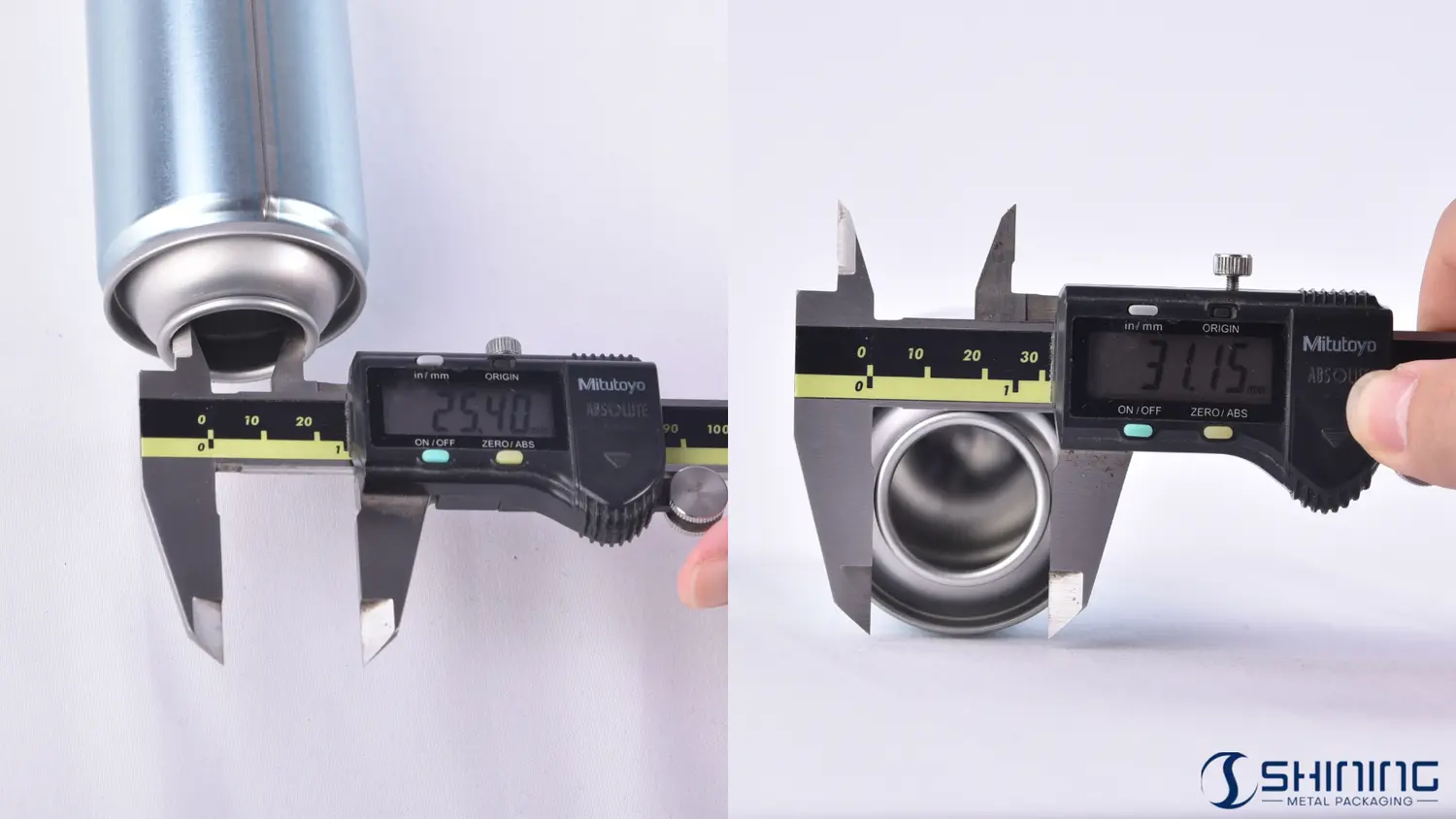

Contact Height (h)

Contact height defines the vertical sealing interface between the valve cup gasket and the can. It is one of the most critical parameters affecting gas tightness and long-term leak performance.

- Measured at 3 equally spaced positions.

- Must be 4.00 mm ± 0.15 mm.

- Difference across three measurements on same can: ≤ 0.2 mm.

Measurement is performed at three equidistant points around the aperture, with strict limits on variation between points to ensure circular consistency.

2.Dimensional Tolerances for Valve Compatibility

Outside Diameter of Aperture

| Parameter | Specified Value (mm) | Control Requirement |

|---|---|---|

| Mean outside diameter | 31.2 ± 0.2 | Batch consistency required |

| Max–Min variation | ≤ 0.2 | Per can |

| Minimum value | ≥31.0 | Absolute limit |

Inside Diameter of Aperture

| Parameter | Specified Value (mm) | Control Requirement |

|---|---|---|

| Mean inside diameter | 25.4 ± 0.1 | Critical sealing dimension |

| Max–Min variation | ≤ 0.15 | Per can |

| Minimum value | ≥25.3 | Valve insertion safety |

Shoulder Height (S1)

Shoulder height ensures sufficient clearance for post-clinch operations, such as mounting moulded plastic actuators or overcaps.

| Can Body Diameter (mm) | Minimum Shoulder Height S1 (mm) |

|---|---|

| 45 | 4.00 |

| 49 | 4.00 |

| 52 | 3.00 |

| 57 | 3.00 |

| 65 | 3.00 |

3.Practical Application Scenarios

Can Manufacturing

For can makers, EN 14847 provides measurable control points that are suitable for routine quality inspection without destructive sectioning.

Filling and Clinching

Fillers rely on these dimensions to set clinching heads correctly, ensuring repeatable sealing across high-speed production lines.

Valve Matching and Procurement

From a sourcing perspective, EN 14847 ensures that cans manufactured by different suppliers remain compatible with standardized 25.4 mm valve cups (EN 14848).

Download the Standard PDF

This document presents EN 14847, specifying dimensional requirements for tinplate aerosol containers with a 25.4 mm aperture. It provides standardized measurement criteria for contact height, diameters, and shoulder height, supporting reliable valve clinching, manufacturing consistency, and quality inspection.

FAQ – Engineering & Purchasing

No. EN 14847 applies specifically to tinplate aerosol containers. Although aluminium cans use the same nominal 25.4 mm aperture, their contact height and deformation behaviour are defined separately in EN 15006.

Radii and angles are difficult to measure consistently without destructive sectioning. Instead, EN 14847 controls functional dimensions that directly influence sealing and clinch performance in production.

ISO 90-3 defines overall can geometry, capacity and height. EN 14847 complements it by defining the functional valve interface required for reliable clinching and sealing.

No. Contact height is measured using dedicated gauges without cutting or damaging the can. This allows routine inspection on production lines and during incoming quality control.

Only if both the can and the valve comply with EN 14847 and EN 14848 respectively. Mixing compliant valves with non-compliant apertures is a common cause of sealing instability.

An undersized aperture can force valve insertion and damage the gasket. This often leads to immediate leaks or delayed sealing failure during storage.

Yes. The tolerances defined in EN 14847 are designed for stable clinching at industrial production speeds. They balance manufacturing capability with sealing reliability.

Yes, especially when decorative overcaps or actuator skirts are used. Insufficient shoulder height frequently causes interference and assembly issues downstream.