Aluminum Gas Cylinder for Fire Extinguishers

Standard

DOT, TPED, GB/T

Material

Aluminium alloy 6061-T6

Applications

residential, commercial, and vehicular fire protection systems

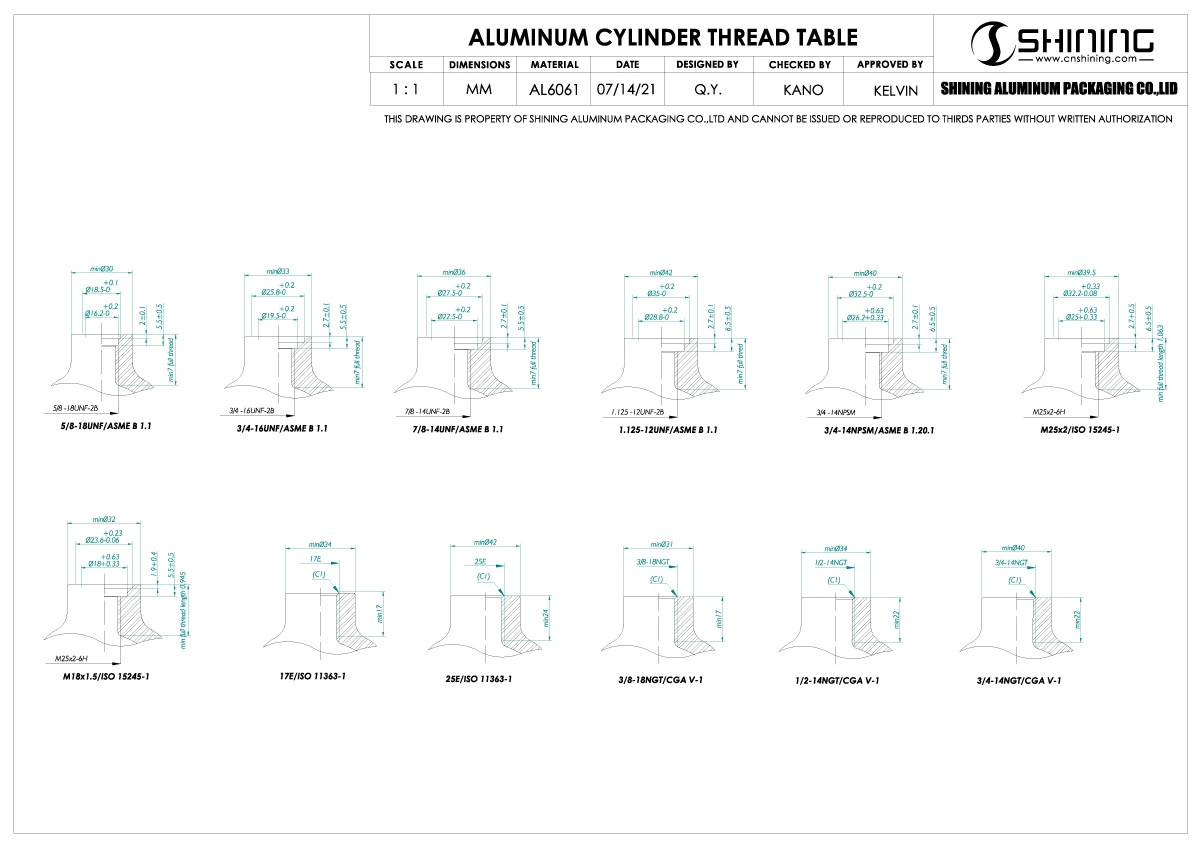

Valve & Thread

Specified & Installed Upon Request

Size

Custom Size is available with the TPED/DOT Certified Range

Finish

Unpainted & Brushed & Different Color Coated

Delivery Time

Usually 30-40 days Upon Quantity

Why Choose Our Aluminum Gas Cylinders?

At Shining Packaging, we specialize in crafting high-quality aluminum gas cylinders and fire extinguishers designed for superior performance in fire protection systems. Made from aluminum alloy 6061-T6, our cylinders are lightweight, corrosion-resistant, and built to meet stringent DOT and TPED standards. Whether for residential, commercial, or vehicular applications, our products ensure reliable fire safety with customizable options to meet your needs.

Advanced Material and Production

Our aluminum gas cylinders are constructed using premium aluminum alloy 6061-T6, analyzed with a spectrum analyzer to guarantee material stability and durability. This ensures our cylinders withstand harsh environments, making them ideal for fire extinguishers in diverse settings. With automated shaping machinery, we achieve seamless cylinder interfaces, enhancing safety and reliability for all fire protection applications.

Customizable Features and Finishes

We offer a range of customization options for our aluminum gas cylinders. Choose from unpainted, brushed, or color-coated finishes to match your aesthetic or functional requirements. Additionally, we provide custom sizes within our DOT/TPED certified range, along with specified valves and threads installed upon request. Share your specifications, and we will deliver tailored solutions with technical illustrations for approval.

Versatile Fire Protection Applications

Our fire extinguishers and aluminum gas cylinders cater to a wide range of fire safety needs:

- Portable Extinguishers: Lightweight and easy to maneuver, perfect for residential and commercial emergencies.

- Automotive Fire Suppression: Compact and durable for vehicles like cars and buses, ensuring reliable fire safety in confined spaces.

- Industrial Fire Protection: Robust and corrosion-resistant, ideal for safeguarding industrial operations.

- Marine Fire Safety: Resistant to saltwater corrosion, our cylinders are essential for fire safety systems on ships and vessels.

Premium Aluminum Gas Cylinders for Fire Safety

We pride ourselves on efficient production and delivery, with standard lead times of 30-40 days depending on order quantity. Our team at Shining Packaging is committed to providing exceptional support, ensuring your aluminum gas cylinders and fire extinguishers meet your exact specifications. Contact us today to discuss your fire protection needs and request a quote.

Aluminum Cylinders Size

DOT 3AL Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 50 | 1.97 | 250 | 3625 | 417 | 6042 | 0.26 | 0.46 | 0.57 | 1.01 | DOT | DOT 3AL | DOT |

| 2 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.35 | 0.65 | 0.77 | 1.43 | DOT | UN ISO7866 | DOT |

| 3 | 61 | 2.40 | 207 | 3000 | 345 | 5000 | 0.4 | 0.7 | 0.88 | 1.54 | DOT | DOT 3AL | DOT |

| 4 | 73.8 | 2.91 | 160 | 2321 | 200 | 2901 | 0.62 | 0.62 | 1.36 | 1.36 | DOT | DOT 39 | DOT |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 6 | 73.8 | 2.91 | 150 | 2176 | 225 | 3263 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 7 | 81.5 | 3.21 | 153 | 2216 | 255 | 3694 | 0.6 | 1.3 | 1.32 | 2.87 | DOT | DOT 3AL | DOT |

| 8 | 81.5 | 3.21 | 124 | 1800 | 207 | 3000 | 0.63 | 1.17 | 1.39 | 2.58 | DOT | DOT 3AL | DOT |

| 9 | 90 | 3.54 | 207 | 3000 | 345 | 5000 | 0.92 | 1.68 | 2.03 | 3.70 | DOT | DOT 3AL | DOT |

| 10 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 1.2 | 2 | 2.65 | 4.41 | DOT | DOT 3AL | DOT |

| 11 | 111.3 | 4.38 | 124 | 1800 | 207 | 3000 | 0.98 | 1.82 | 2.16 | 4.01 | DOT | DOT 3AL | DOT |

| 12 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 2.52 | 4.68 | 5.56 | 10.32 | DOT | DOT 3AL | DOT |

| 13 | 133.4 | 5.25 | 153 | 2216 | 255 | 3694 | 3.9 | 7 | 8.60 | 15.43 | DOT | DOT 3AL | DOT |

| 14 | 133.4 | 5.25 | 124 | 1800 | 207 | 3000 | 2.38 | 4.42 | 5.25 | 9.74 | DOT | DOT 3AL | DOT |

TPED EN ISO7866 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.4 | 0.67 | 0.88 | 1.48 | TPED | EN ISO7866 | TUV |

| 2 | 60.5 | 2.38 | 200 | 2901 | 300 | 4351 | 0.35 | 0.7 | 0.77 | 1.54 | TPED | EN ISO7866 | TUV |

| 3 | 80 | 3.15 | 32 | 464 | 48 | 696 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TI |

| 4 | 70 | 2.76 | 120 | 1740 | 180 | 2611 | 0.2 | 1.2 | 0.44 | 2.65 | TPED | EN ISO11118 | TUV |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.3 | 0.44 | 2.87 | TPED | EN ISO11118 | TUV |

| 6 | 81.5 | 3.21 | 124 | 1798 | 186 | 2698 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TUV |

| 7 | 90 | 3.54 | 200 | 2901 | 300 | 4351 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 8 | 90 | 3.54 | 166 | 2408 | 250 | 3626 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 9 | 111 | 4.37 | 124 | 1798 | 186 | 2698 | 1.4 | 3.9 | 3.09 | 8.60 | TPED | EN ISO7866 | TUV |

| 10 | 111 | 4.37 | 200 | 2901 | 300 | 4351 | 1.4 | 4 | 3.09 | 8.82 | TPED | EN ISO7866 | TUV |

| 11 | 120 | 4.72 | 166 | 2408 | 250 | 3626 | 1.4 | 4.5 | 3.09 | 9.92 | TPED | EN ISO7866 | TUV |

| 12 | 140 | 5.51 | 166 | 2408 | 250 | 3626 | 4 | 8 | 8.82 | 17.64 | TPED | EN ISO7866 | TUV |

| 13 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TPED | EN ISO7866 | TUV |

| 14 | 184 | 7.24 | 166 | 2408 | 250 | 3626 | 6 | 15 | 13.23 | 33.07 | TPED | EN ISO7866 | TUV |

| 15 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 16 | 13.23 | 35.27 | TPED | EN ISO7866 | TUV |

| 16 | 203 | 7.99 | 166 | 2408 | 250 | 3626 | 11 | 20 | 24.25 | 44.09 | TPED | EN ISO7866 | TUV |

GB/T 11640 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test Pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 150 | 2176 | 225 | 3263 | 0.2 | 0.6 | 0.44 | 1.32 | TS | GB/T 11640 | TS |

| 2 | 60 | 2.36 | 300 | 4351 | 450 | 6527 | 0.2 | 0.5 | 0.44 | 1.10 | TS | GB/T 11640 | TS |

| 3 | 81.5 | 3.21 | 150 | 2176 | 225 | 3263 | 0.7 | 1.5 | 1.54 | 3.31 | TS | GB/T 11640 | TS |

| 4 | 111.3 | 4.38 | 200 | 2901 | 300 | 4351 | 1.1 | 4 | 2.43 | 8.82 | TS | GB/T 11640 | TS |

| 5 | 140 | 5.51 | 150 | 2176 | 225 | 3263 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 6 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 7 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 15 | 13.23 | 33.07 | TS | GB/T 11640 | TS |

| 8 | 203 | 7.99 | 150 | 2176 | 225 | 3263 | 8 | 20 | 17.64 | 44.09 | TS | GB/T 11640 | TS |

Production Process

At Shining Packaging, we deliver top-tier aluminum Fire Extinguishers cylinders with unmatched precision and quality. Our state-of-the-art process includes: