The global aerosol spray market, encompassing products like popcorn ceiling spray, was valued at $28.32 billion in 2023 and is projected to reach $46.59 billion by 2031, growing at a compound annual growth rate (CAGR) of 6.45%, according to Verified Market Research. Popcorn ceiling spray, though a niche segment, remains relevant in repair and restoration projects for older homes due to its cost-effective and convenient application. This market growth reflects a rising demand for aerosol-based solutions in construction and home improvement, driven by their ease of use and efficiency in delivering textured finishes. These statistics highlight the continued significance of aerosol sprays in specific applications despite evolving design trends.

Introduction to the Guide

This article serves as a comprehensive guide to popcorn ceiling aerosol spray, exploring its uses, benefits, and limitations. From understanding its role in home maintenance to navigating health concerns and application techniques, we’ll provide practical insights for homeowners and contractors. Whether you’re repairing a vintage ceiling or considering alternatives, this guide will help you make informed decisions about aerosol can products.

What Is popcorn ceiling aerosol spray?

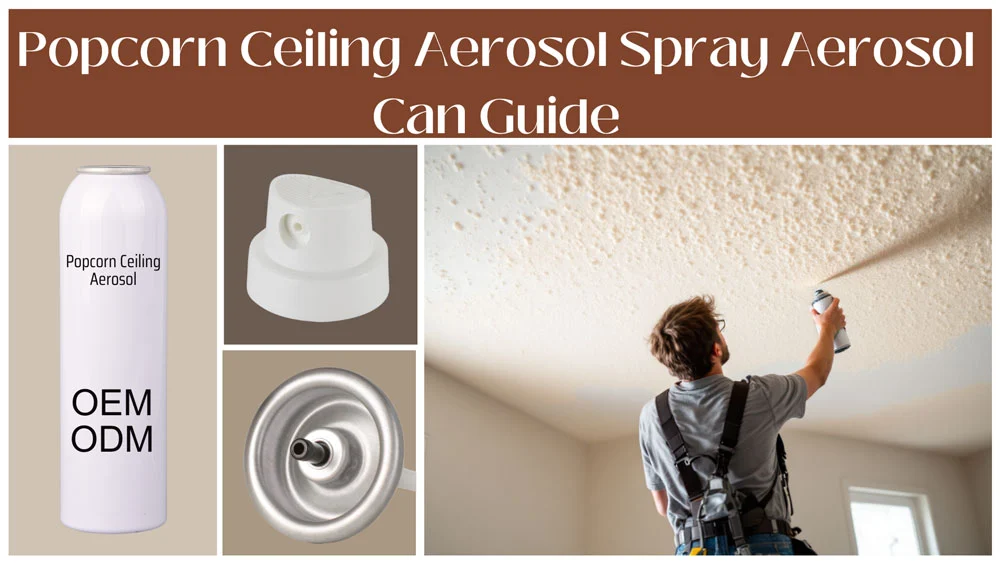

As a leading aluminum aerosol can manufacturer, I’m thrilled to showcase our popcorn ceiling aerosol spray cans, designed for seamless ceiling repairs. Our durable aluminum cans deliver a specialized spray that replicates the bumpy texture of popcorn ceilings, perfect for fixing stains, cracks, or small damaged areas. These cans are lightweight, recyclable, and engineered for precise application—just shake and spray for a professional finish. With textures ranging from fine to coarse, our sprays match any ceiling style, and the dried texture is paintable for a flawless blend. Ideal for DIYers and small projects, our aluminum cans ensure reliability and ease. Explore our guide to choose the perfect spray and elevate your ceiling projects!

I take pride in producing high-quality aluminum aerosol cans for popcorn ceiling repairs, offering unmatched durability and eco-friendly design. Our cans provide consistent, mess-free texture application, making them ideal for homeowners or contractors tackling touch-ups without bulky equipment. Safety is crucial—use our sprays in well-ventilated spaces and wear protective gear. For pre-1980s ceilings, test for asbestos first. Our aluminum cans are optimized for small-scale repairs, with nozzles crafted for precision. Built to last, they resist corrosion and ensure long-lasting performance. Visit our guide for expert tips on selecting and using our aluminum aerosol sprays to achieve stunning ceiling results!

Mastering Popcorn Ceiling Aerosol Spray: Your Guide to Flawless Ceiling Repairs

Popcorn ceilings, those textured relics of mid-20th-century design, can be a headache to maintain. Whether you’re dealing with stains, cracks, or just want to refresh an outdated look, popcorn ceiling aerosol spray offers a convenient solution for DIY enthusiasts and contractors alike. As someone who’s tackled ceiling repairs firsthand, I can tell you that using an aerosol spray designed for popcorn textures is a game-changer. It’s quick, relatively mess-free compared to traditional methods, and can blend seamlessly with existing textures. But before diving in, let’s explore why popcorn ceiling spray is a go-to choice and how to use it effectively. Here’s a pro tip: always test your spray pattern on a piece of cardboard first to avoid uneven application. This little trick saves time and ensures a professional finish.

Understanding Popcorn Ceiling Aerosol Spray and Its Benefits

When I first encountered a damaged popcorn ceiling in my home, I was overwhelmed by the idea of matching that iconic bumpy texture. That’s where popcorn ceiling aerosol spray for specific textures (e.g., fine, medium, coarse) comes in. These sprays are formulated to replicate the exact texture of your ceiling, whether it’s a fine stipple or a coarse, chunky finish. The beauty of using an aerosol spray to fix damaged popcorn ceiling lies in its precision. Unlike heavy machinery or messy patching compounds, these cans are lightweight and equipped with vertical spray tips for easy application. I’ve found that low VOC popcorn ceiling aerosol spray is a must for indoor projects, as it minimizes fumes and makes cleanup a breeze with just soap and water. For those worried about health and sustainability, look for products with sustainability certifications for popcorn ceiling texture products packaging to ensure eco-friendly choices. A quick tip: shake the can vigorously for at least a minute to ensure the texture mixes evenly for a consistent spray.

Safety First: How to Tell if a Popcorn Ceiling Has Asbestos?

Before you even think about spraying, you need to address a critical question: does your ceiling contain asbestos? Popcorn ceilings installed before the 1980s often included asbestos, a hazardous material linked to serious health risks. I learned this the hard way when renovating an older home. To check, don’t just start scraping! Instead, hire a professional to take a small sample and test it in a certified lab. Visual inspection isn’t enough, as asbestos fibers are microscopic. If asbestos is present, you’ll need to consult a remediation expert before using any popcorn ceiling aerosol spray. For safe ceilings, mildew resistant popcorn ceiling spray is a fantastic choice, especially in humid areas like bathrooms, as it prevents mold growth. My go-to hack? Ventilate the room well during application to keep the air clear and reduce health risks.

Choosing the Right Popcorn Ceiling Spray for Your Project

So, what should you spray a popcorn ceiling with? The answer depends on your needs. For small touch-ups, a popcorn ceiling touch up spray for small areas is perfect. These cans are designed for quick fixes, like covering water stains or minor cracks. For larger repairs, a Ceiling Texture Sprayer or ceiling texture spray can handle bigger areas with a consistent finish. I once used a water based popcorn ceiling texture spray aerosol to repair a ceiling after a leak, and the results were seamless. The water-based formula dried in about 30 minutes, allowing me to paint over it the same day. If you’re aiming to match popcorn ceiling texture, look for a product labeled for your specific texture type. A secret weapon? Hold the can at a 45-degree angle for better control and a more natural texture match.

Step-by-Step: Popcorn Ceiling Aerosol Spray Instructions

Using a popcorn ceiling aerosol spray is straightforward, but technique matters. First, prep the room: cover furniture, floors, and walls with drop cloths, as overspray can be messy. I learned this after a few specks landed on my couch! Next, clean the ceiling to remove dust or grease, which can affect adhesion. Shake the can for at least a minute, then test the spray on a scrap surface. When applying, hold the can 8-12 inches from the ceiling and use short, controlled bursts to repair damaged popcorn ceiling. For an even finish, overlap each pass slightly. If you’re using an easy to use popcorn ceiling aerosol spray, the vertical nozzle makes this a breeze. After spraying, let it dry for 30-60 minutes before inspecting. Pro tip: if the texture looks too heavy, lightly dab it with a dry sponge to soften the peaks.

Tips for Best Aerosol Spray for Matching Popcorn Ceiling Texture

Matching an existing ceiling texture can feel like solving a puzzle, but the best popcorn ceiling spray makes it easier. Look for products labeled for acoustic ceiling spray or spray on ceiling finish, as these are designed to mimic the classic popcorn look. I’ve found that practicing on a piece of drywall helps nail the technique before tackling the actual ceiling. For small imperfections, a hide ceiling imperfections spray can work wonders without needing a full texture overhaul. Contractors looking for cost-effective popcorn ceiling texture solutions for contractors should opt for high-yield cans that cover more square footage. A lesser-known trick? Adjust the nozzle pressure (if adjustable) to fine-tune the texture density, ensuring a perfect match every time.

Conclusion

This guide delves into the fundamentals of popcorn ceiling aerosol spray, focusing on the critical role of high-quality aerosol packaging. As an experienced manufacturer specializing in aluminum aerosol cans, we craft a range of empty cans from 30ml to 800ml, tailored for products like popcorn ceiling spray. Our offerings include a complete set of precision-engineered valves and actuators to ensure seamless application. For those seeking full-service solutions, we provide OEM filling services, using either our proven formulas or custom blends developed to meet your specific needs. A quick tip: when selecting a can for popcorn ceiling aerosol spray for specific textures (e.g., fine, medium, coarse), opt for a valve designed for vertical spraying to achieve a consistent texture match.

We pride ourselves on a streamlined 30-day delivery timeline, backed by 35 years of expertise in aluminum can manufacturing. For the U.S. market, our products meet stringent US DOT 2P and 2Q certifications, ensuring safety and reliability. Whether you’re a contractor seeking cost-effective popcorn ceiling texture solutions for contractors or a DIY enthusiast tackling a popcorn ceiling repair, our packaging solutions are designed to deliver. Curious about how our cans can elevate your ceiling texture spray projects? Reach out today to explore packaging details and discover how our expertise can support your next project!

FAQ: Your Popcorn Ceiling Aerosol Spray Questions Answered

1. Where can I buy popcorn ceiling aerosol spray?

You can find popcorn ceiling spray at major home improvement stores like Lowe’s or online retailers. Check the paint or drywall section for popcorn ceiling spray Lowes or similar products. Always ensure the product matches your texture needs and check for sustainability certifications for popcorn ceiling texture products packaging if eco-friendliness is a priority.

2. How long does it take for popcorn ceiling spray to dry?

Most water based popcorn ceiling texture spray aerosol dries in 30-60 minutes, depending on humidity and ventilation. For best results, wait at least 24 hours before painting over the repaired area to ensure full curing.

3. What is the best spray for removing popcorn ceilings?

Removing popcorn ceilings typically requires a water-based solution sprayed via a garden sprayer, not an aerosol spray. Soak the texture, let it sit for 15-20 minutes, then scrape gently. Always test for asbestos first, as removal can release harmful fibers.

4. How to apply popcorn ceiling aerosol spray evenly?

To apply popcorn ceiling aerosol spray evenly, hold the can 8-12 inches from the surface, use short bursts, and overlap passes slightly. Test the spray pattern on cardboard first, and keep the can moving to avoid buildup. Using an easy to use popcorn ceiling aerosol spray with a vertical nozzle helps maintain consistency.

5. Can you paint over popcorn ceiling aerosol repair?

Yes, you can paint over popcorn ceiling repair once it’s fully dry, typically after 24 hours. Use a textured ceiling paint for best results, applied with a roller for even coverage. Ensure the repair blends with the existing texture before painting.

Bonus Tip: Aerosol Valve Supply

The quality of the aerosol valve in popcorn ceiling aerosol spray cans is crucial for consistent application. High-quality valves ensure precise spray patterns, reducing waste and improving texture matching. Check with suppliers like those at aerosol valve for reliable aerosol components to meet your project demands.