Aluminum Powder Bottle Manufacturer

Aluminum Powder Bottle

Discover the ultimate solution for packaging talcum powder, cosmetics, and industrial products with Shining Packaging’s Aluminum Powder Bottles. As a leading manufacturer and supplier, we deliver lightweight, durable bottles designed to protect against moisture, light, and contaminants. Their sleek, customizable design elevates your brand, ensuring your products stand out in a competitive market.

Capacity

100-1000ML

Diameter

40,45,50,53,59,66,74,80mm

Height

100-260mm

Neck Thread

28mm, 38mm

Accessories

Aluminum Powder Cap(Screw or Insert)

Interior coating

Standard EP, polyester-based coatings, compatibility tests recommended

Exterior coatings and printing

Offset printing, heat transfer printing, silk screen printing

MOQ

5000/10,000/20,000 Pcs,

According to bottle type

Key Features

Detail of Aluminum Powder Bottle

—01

Versatile Capacities and Customization

Our Aluminum Powder Bottles come in a range of capacities from 100ml to 1000ml, with custom sizes available to meet your specific needs. Choose between plug or screw-top openings to seamlessly integrate with your production equipment, ensuring operational efficiency.

- 100ml, 150ml, 200ml, 250ml, 300ml, 400ml, 500ml, 750ml, 1000ml

- 2oz, 4oz, 8oz, 16oz, 32oz

—02

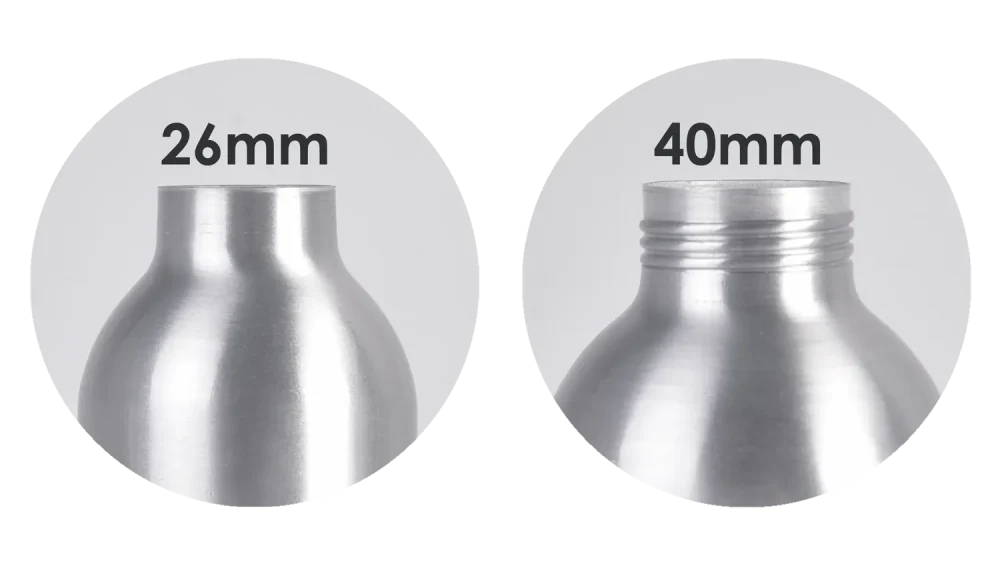

Seamless Compatibility for Powder

Our Aluminum Powder Bottles feature 26mm and 40mm neck sizes, compatible with precision powder caps for seamless production integration. The 26mm suits plug closures, while the 40mm supports screw-tops, ensuring mess-free dispensing. No costly adjustments needed. Customize caps in various colors to match your brand, enhancing market presence efficiently.

- 26mm

- 40mm

—03

Premium Printing for Brand Impact

Make your brand unforgettable with our advanced printing options, including silk screen and heat transfer printing. These techniques deliver vibrant, durable designs that capture attention and reflect your brand’s unique identity, creating packaging as distinctive as your product.

- Offset printing

- heat transfer printing

- silk screen printing

—04

Advanced Protection for Product Integrity

Our bottles feature specialized internal coatings from PPG and Valspar tailored to prevent degradation and ensure compatibility with your product. Through rigorous compatibility testing, we guarantee packaging that upholds the highest standards of quality and safety, preserving the integrity of your powders.

- PPG

- Valspar

Aluminum Powder Bottle Cases

Aluminum Powder Bottle Manufacturer

Shining Packaging is a professional aluminum powder bottle manufacturer. Our aluminium bottles are produced using fully automated production lines, with each line capable of manufacturing 100-150 bottles per minute. Our lines operate 24/7, ensuring product consistency and reliable delivery times.

Aluminum Powder Bottle Supplier

Shining Packaging is a professional aluminum powder bottle supplier. We hold ISO9001 and Sedex certifications, and all our aluminum bottles pass FDA and LFGB food-grade tests. Additionally, we offer comprehensive one-stop packaging services with strict quality inspection processes.

- Our Services

- Product Projection Mapping

- 3D Renderings

- Printing design draft

- 3D printing

- UV digital printing

- Filling suggestions

- Our Quality Control

- Secure Seal Test (SST)

- Removal Torque Test

- Cross-cut Test

- Inner coating test

- Capping Test

- Bottle Size Test

Related Products

Have Questions?

Frequently Asked Questions

What materials are used in your Aluminum Powder Bottles?

Our bottles are crafted from high-purity aluminum, offering exceptional durability and full recyclability.

Are these bottles suitable for food-grade products?

Yes, we provide internal coatings that comply with food safety standards, ideal for food and pharmaceutical applications.

Can I customize the size and shape of the bottles?

Absolutely, we offer tailored sizing and shaping options to perfectly match your product requirements.

How can I ensure the internal coating is compatible with my product?

Our expert team conducts compatibility testing and provides guidance based on your product’s composition.

Can I request samples before placing a bulk order?

Yes, we offer samples to ensure quality and support confident decision autodidact decision-making.

What are the production and delivery timelines?

Lead times vary based on order size and complexity, but standard orders are typically delivered within 4-6 weeks.