Standard Overview

FEA 215 is an industry standard issued by the European Aerosol Federation (FEA), defining the critical dimensions and tolerances of 20 mm openings on monobloc aluminium aerosol containers.

Unlike EN or ISO standards, FEA 215 reflects harmonised industry practice, aimed at ensuring reliable sealing when used with valves manufactured according to EN 14849 (glass valve ferrules).

1. Why a 20 mm Opening Standard?

The 20 mm opening system is widely used for:

- Cosmetic and personal care aerosols

- Pharmaceutical or medical sprays

- Compact aluminium monobloc containers

FEA 215 aims to standardise one preferred shoulder profile—most commonly ogival— to reduce variability in sealing behaviour across suppliers.

2. Scope and Application

This standard applies to:

- Monobloc aluminium aerosol containers

- Nominal opening diameter of 20 mm

- Preformed bead profiles with outward curl

3. Critical Dimensions Explained

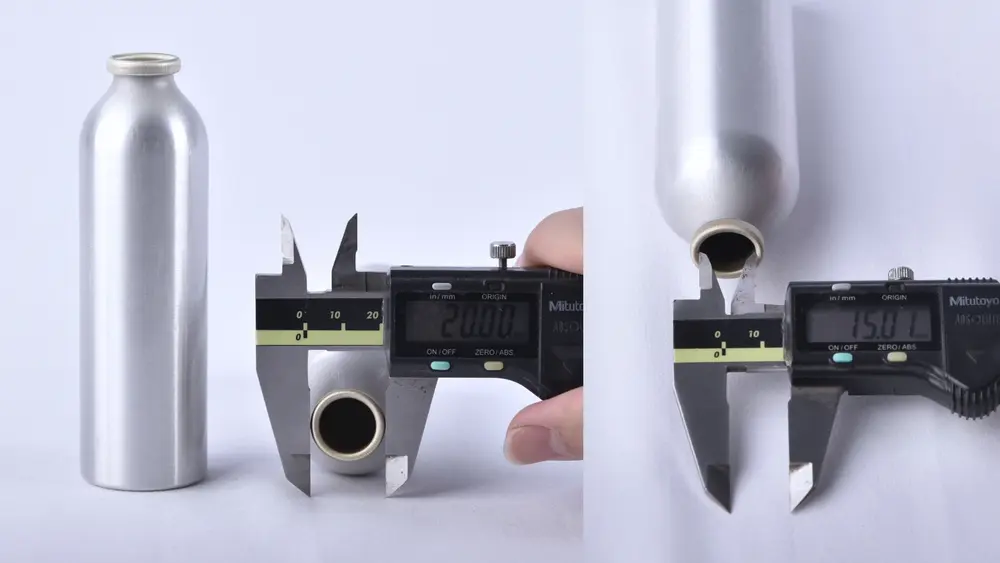

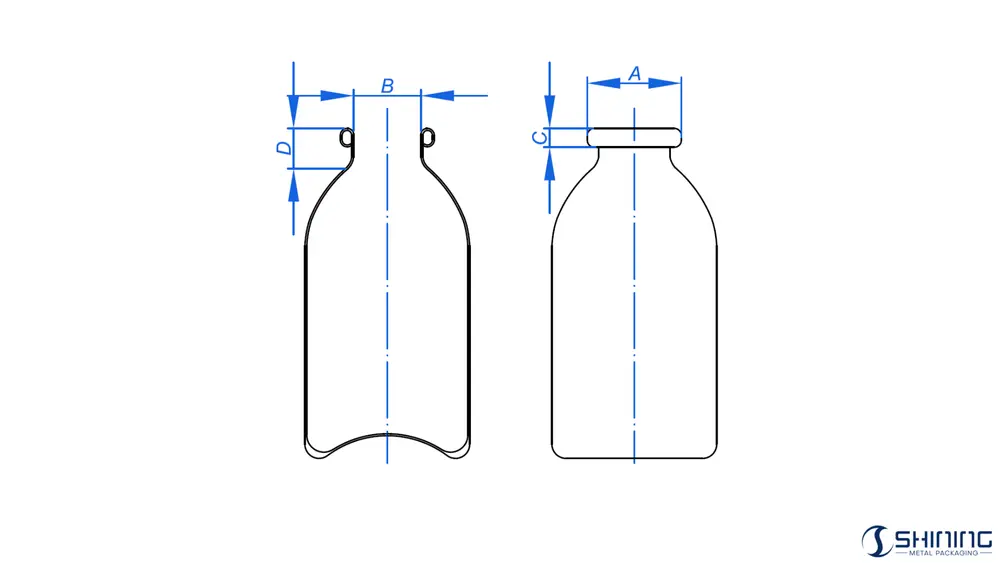

Instead of specifying complex radii, FEA 215 defines a compact set of functional dimensions that directly influence valve crimping and gasket compression.

Dimensional Requirements

| Dimension | Requirement (mm) | Functional Meaning |

|---|---|---|

| A – Opening diameter | 20.0 +0 / −0.2 | Valve insertion and centering |

| B – Upper profile width | 15.0 ± 0.5 | Valve ferrule support |

| C – Bead height | 4.0 ± 0.3 | Clinch deformation control |

| D – Shoulder height | ≥ 8.0 | Clearance for valve components |

4. Relationship with Other Standards

FEA 215 fits into the wider aerosol standards ecosystem as follows:

- EN 14849 – defines valve ferrules compatible with 20 mm systems

- EN 15006 / EN 15010 – apply to 25.4 mm aluminium systems, not interchangeable

The 20 mm and 25.4 mm systems are not directly interchangeable and require dedicated valves and clinch tooling.

5. Practical Application Scenarios

Container Manufacturing

FEA 215 provides stable dimensional targets for forming, necking, and bead creation in aluminium monobloc cans.

Valve Crimping

Compliance with FEA 215 ensures predictable crimp deformation when used with EN 14849-compliant valve ferrules.

Procurement and Supplier Alignment

Specifying FEA 215 in purchase documents reduces the risk of incompatible container–valve combinations.

Download the Standard PDF

This document provides FEA 215, defining standardized dimensions and tolerances for 20 mm openings in monobloc aluminium aerosol containers. It supports consistent shoulder profiles, secure valve sealing, and reliable crimping performance across manufacturing and quality control applications.

FAQ – Engineering & Purchasing

FEA 215 is not a legal requirement, but it is widely adopted as industry best practice for 20 mm aluminium aerosol containers. In many supply chains, it is treated as a de facto standard to ensure sealing reliability and interchangeability.

No. The 20 mm and 25.4 mm systems are fundamentally different in geometry, ferrule design, and clinching behavior. Attempting to mix these systems almost always results in sealing instability or mechanical interference.

Limiting the shoulder profile reduces variability in crimp deformation and gasket compression. This simplifies tooling design and improves consistency across different container and valve suppliers.

No. FEA 215 focuses strictly on opening geometry and dimensional compatibility. Pressure resistance is governed by container wall thickness, material properties, and applicable safety standards.

No, but a machined curl is recommended for larger diameters or higher cosmetic requirements. It improves dimensional consistency and reduces variability during valve crimping.

Yes, flat shoulders are permitted, but ogival shoulders are the most commonly used in practice. Ogival profiles provide smoother stress distribution and more predictable sealing behavior.

Yes, especially for cosmetic and pharmaceutical aerosol products. Explicitly referencing FEA 215 helps prevent incompatible container–valve combinations in multi-supplier sourcing.