Standard Overview

EN 14849 is a European Standard that defines the critical dimensions of aerosol valve ferrules used on glass aerosol containers. Its primary objective is to ensure reliable fastening and sealing of aerosol valves on glass neck finishes.

Within the aerosol packaging ecosystem, EN 14849 plays a unique role: it establishes the valve-side geometry for 20 mm systems, while container-side geometries are defined separately by glass or aluminium container standards.

1. Scope and Application

This standard applies to aerosol valves intended for use with glass containers having nominal neck finishes of 11, 13, 15, 17, 18 and 20 mm.

Although originally written for glass containers, the ferrule geometries defined in EN 14849 are also widely referenced as a dimensional benchmark for 20 mm aerosol valve systems.

2. Ferrule Geometry – Functional Interpretation

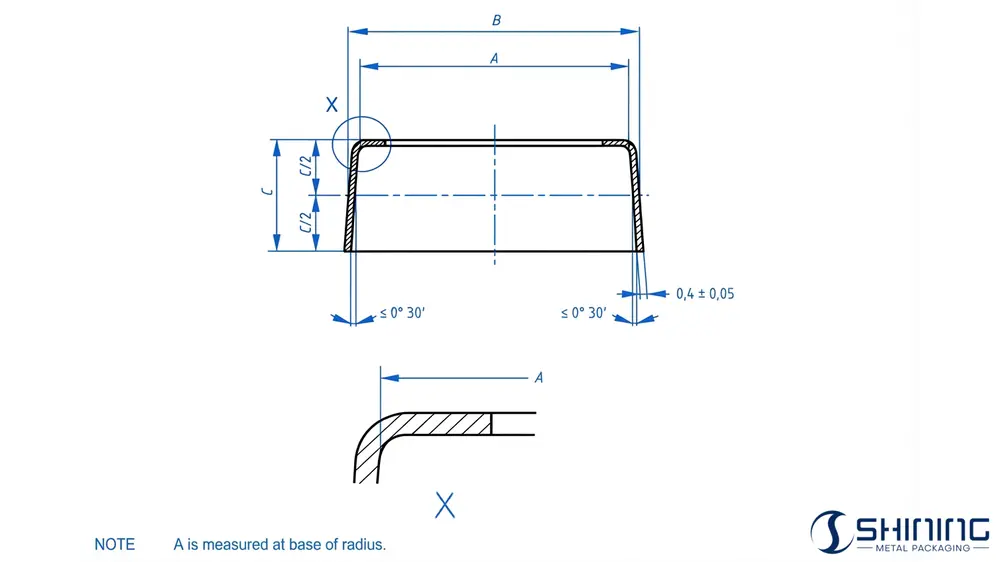

The standard defines three primary dimensions—A, B and C— which together control valve positioning, sealing and crimp stability.

Dimension A – Internal Diameter

Dimension A defines the minimum internal diameter of the ferrule, ensuring proper fit over the glass neck finish without excessive stress.

Dimension B – External Diameter

Dimension B controls the outer envelope of the ferrule and directly affects how the ferrule interacts with crimping tools.

Dimension C – Ferrule Height

Dimension C defines the vertical engagement range during crimping. Minimum and maximum values are specified to ensure adequate deformation without over-stressing the glass container.

3. Dimensional Requirements

| Nominal Neck Finish (mm) | Internal Ø A (min) | External Ø B (±0.1) | Ferrule Height C (min) | Ferrule Height C (max) |

|---|---|---|---|---|

| 11 | 11.05 | 12.0 | 4.7 | 7.1 |

| 13 | 13.35 | 14.3 | 4.7 | 7.1 |

| 15 | 15.35 | 16.3 | 5.5 | 7.9 |

| 17 | 16.9 | 17.9 | 5.9 | 8.3 |

| 18 | 18.6 | 19.6 | 5.5 | 8.3 |

| 20 | 20.1 | 21.1 | 5.6 | 9.0 |

4. Relationship with Other Standards

EN 14849 integrates into the broader aerosol standards framework as follows:

Together, these standards ensure dimensional compatibility across container material, valve design and crimping tools.

5. Practical Application Scenarios

Glass Aerosol Packaging

EN 14849 provides a controlled interface that minimizes breakage risk while ensuring reliable valve fastening.

Valve Design and Manufacturing

Valve manufacturers use EN 14849 as the baseline geometry for ferrules intended for glass containers and 20 mm systems.

Procurement and Supplier Alignment

Specifying EN 14849 reduces the risk of mismatched valves and glass containers from different suppliers.

Download the Standard PDF

This document provides EN 14849, defining dimensional requirements for aerosol valve ferrules used with glass containers. It specifies critical internal and external dimensions to ensure secure valve fastening and consistent compatibility across standardized glass aerosol packaging systems.

FAQ – Engineering & Purchasing

Formally, EN 14849 applies to aerosol valves intended for glass containers. However, its ferrule geometry is widely referenced as a dimensional benchmark for 20 mm aerosol systems due to its proven sealing behavior.

Yes, but only when the aluminium container opening is designed specifically for a 20 mm ferrule system. Using EN 14849 ferrules on incompatible openings significantly increases the risk of poor sealing or deformation.

The minimum height ensures sufficient engagement and sealing during crimping. The maximum height limits stress transfer to the glass neck finish, reducing the risk of cracking or breakage.

No. EN 14849 is strictly related to 20 mm systems. The geometry, tooling, and sealing principles of 20 mm and 25.4 mm systems are fundamentally different and not interchangeable.

No. EN 14849 defines only ferrule geometry and dimensional limits. Crimping force, head load, and process parameters must be defined separately by equipment guidelines or industry practices.

Yes. EN 14854 defines the glass container neck finish that the ferrule must fit. Without matching neck finish dimensions, even a compliant ferrule cannot ensure reliable sealing.

Yes, especially for glass aerosol packaging where tolerance margins are limited. Referencing EN 14849 helps align valve, container, and tooling requirements across suppliers.