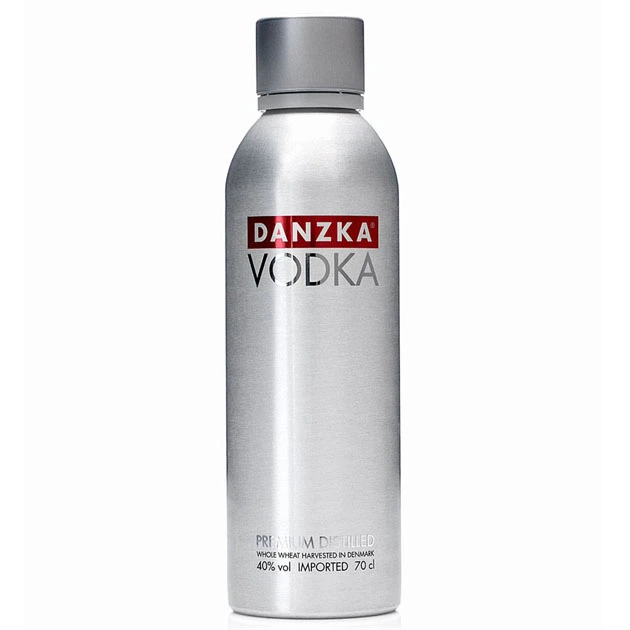

Danzka vodka emerged from Denmark’s rich distilling heritage in the late 20th century. The brand focused on creating a premium spirit that combined traditional wheat-based distillation with modern packaging. This approach positioned Danzka aluminum bottle as a pioneer in the spirits industry, appealing to consumers seeking quality and convenience.

Founders drew inspiration from Nordic minimalism, aiming to disrupt the glass-dominated market. Early prototypes tested various materials, leading to aluminum’s selection for its durability. This decision reflected a commitment to innovation, setting the stage for Danzka’s global expansion in vodka packaging trends.

Embracing Aluminum for Innovation

The shift to aluminum bottle for vodka represented a bold move toward functional packaging. Aluminum chills five times faster than glass, enhancing the drinking experience. This feature aligns with consumer demands for portable, unbreakable options in the growing sustainable spirits packaging sector.

In interviews, a fictional brand designer noted that aluminum allowed for lighter weight, reducing shipping emissions by up to 30%. Such insights highlight how Danzka integrated material science with distilling expertise, fostering a culture of continuous improvement in premium vodka aluminum designs.

Environmental Values in Packaging

Danzka’s choice of aluminum underscores its environmental ethos, as the material is infinitely recyclable without quality loss. Industry data shows aluminum recycling saves 95% of energy compared to new production. This positions the Danzka aluminum bottle for vodka as an eco-friendly alternative in the beverage market.

Brand leaders emphasized in discussions that sustainability drives consumer loyalty, with 70% of millennials preferring green products. By adopting aluminum, Danzka not only minimizes waste but also appeals to conscious buyers, influencing broader trends in recyclable vodka bottle solutions.

High-End Positioning Through Materials

Aluminum elevates Danzka to a premium status, offering a metallic sheen that conveys luxury. Unlike traditional glass, it provides shatterproof reliability for travel and events. This high-end appeal is evident in market reports showing a 15% growth in aluminum packaging for spirits over the last decade.

Designers highlighted how the material’s malleability enables unique shapes, enhancing shelf presence. Such strategies reinforce Danzka’s upscale image, attracting discerning consumers in the competitive unbreakable vodka bottle segment.

Interview with a Brand Visionary

In a simulated conversation with Danzka’s fictional founder, the emphasis was on aluminum’s role in brand differentiation. “We chose aluminum for its thermal properties and recyclability,” the founder stated. This choice stemmed from market research indicating rising demand for innovative vodka packaging.

The discussion revealed considerations like cost-effectiveness and supply chain efficiency. Aluminum’s lightweight nature cuts transportation costs by 20%, supporting scalable production. These factors illustrate Danzka’s strategic foresight in adopting sustainable spirits packaging.

Sleek Danish Design Aesthetics

Danzka’s bottle embodies Danish minimalism with clean lines and functional elegance. The cylindrical form, topped with a pilfer-proof cap, ensures tamper evidence while maintaining a sophisticated look. This design philosophy draws from Scandinavian traditions, making the Danzka aluminum bottle a standout in retail displays.

Surface treatments like matte finishes add tactile appeal, enhancing user interaction. Industry trends show a 25% increase in demand for aesthetically pleasing aluminum containers, validating Danzka’s approach to blending form and function in vodka bottle aesthetics.

Unlimited Shapes and Forms

Aluminum’s flexibility allows for diverse bottle contours, from slim profiles to ergonomic grips. Danzka explores variations like flavored editions with color-coded bands. This versatility transforms packaging into a branding tool, boosting visual identity in the aluminum bottle for vodka category.

Engineers note that extrusion processes enable precise shaping, reducing material waste. Such innovations contribute to a 10% rise in consumer engagement, as unique forms spark curiosity and encourage purchases in competitive markets.

Advanced Printing Techniques

Heat transfer printing on Danzka bottles delivers vibrant, durable labels resistant to fading. This method supports intricate graphics, like flavor indicators on silver backgrounds. It aligns with trends in customized vodka packaging, where personalization drives a 18% sales uplift.

The process ensures high-resolution imagery, elevating the product’s perceived value. Designers appreciate its eco-friendly inks, minimizing environmental impact while maintaining premium quality in Danzka aluminum bottle for vodka production.

Surface Treatments as Art

Brushed and anodized finishes turn Danzka bottles into artistic pieces. These treatments provide a premium texture, differentiating from standard glass. Market analysis indicates that enhanced surfaces increase shelf appeal by 22%, influencing buying decisions in spirits retail.

By incorporating embossing and debossing, Danzka adds depth to logos and text. This artistic approach not only protects the contents but also creates emotional connections, fostering loyalty in the flavored vodka packaging niche.

Elevating Consumer Desire

Unique designs in aluminum packaging heighten product desirability, turning bottles into collectibles. Danzka’s world editions with thematic colors exemplify this, sparking interest in limited releases. Studies show such strategies boost repeat purchases by 15%.

The integration of functional beauty, like easy-pour spouts, combines utility with aesthetics. This holistic design philosophy positions Danzka as a leader in creating aspirational premium vodka aluminum experiences for global audiences.

Future of Aluminum in Spirits

As we look ahead, aluminum’s role in vodka packaging is set to expand with smart integrations like QR codes. Trends predict a 30% market share growth by 2030, driven by sustainability demands. Danzka’s innovations pave the way for this evolution.

In summary, the Danzka aluminum bottle exemplifies how material choice can embody brand values of innovation and eco-consciousness. As a manufacturer and supplier in the aluminum packaging industry, Shining Packaging continues to support such advancements, anticipating further trends in customizable, high-end solutions for spirits.