Aluminum Gas Cylinders For Paintball

Standard

DOT, TPED, GB/T

Material

Aluminium alloy 6061-T6

Applications

Paintball

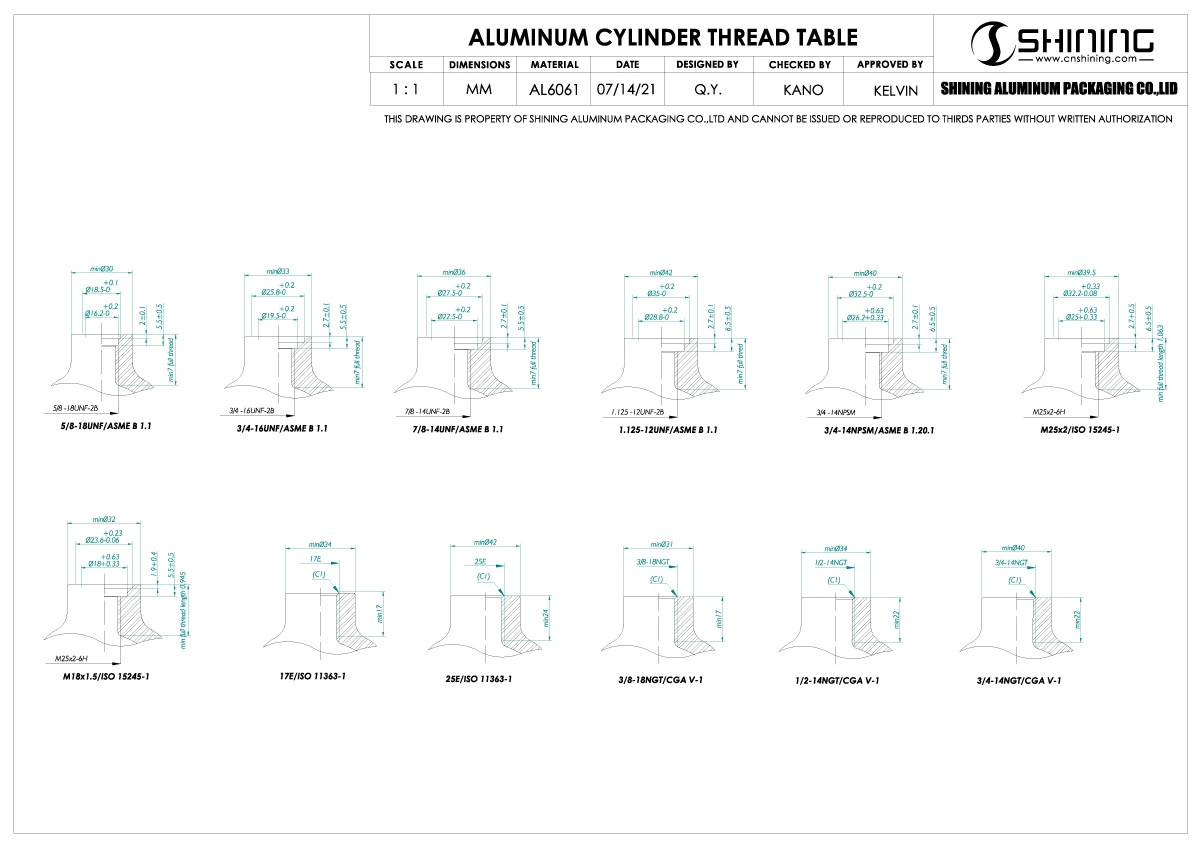

Valve & Thread

Specified & Installed Upon Request

Size

Custom Size is available with the TPED/DOT Certified Range

Finish

Unpainted & Brushed & Different Color Coated

Delivery Time

Usually 30-40 days Upon Quantity

High-Quality Aluminum Gas Cylinder Design

At Shining Packaging, we specialize in manufacturing high-performance Aluminum Gas Cylinders designed specifically for paintball enthusiasts and professionals. Crafted from premium aluminium alloy 6061-T6, our cylinders ensure durability, lightweight handling, and compliance with international standards such as DOT, TPED, and GB/T. These cylinders are engineered to deliver reliable CO2 and compressed air supply, enhancing player performance during intense paintball competitions.

Customizable Paintball Cylinder Features

Our paintball cylinders offer extensive customization options to meet diverse needs. Choose from a variety of surface finishes, including unpainted, brushed, or color-coated options, to align with your brand or personal style. We also provide custom valve and thread installations upon request, ensuring seamless integration with your paintball equipment. With custom size availability within the certified DOT/TPED range, we cater to specific requirements, delivering tailored solutions for every order.

Advanced Manufacturing for Paintball Cylinders

Our state-of-the-art production process utilizes a spectrum analyzer to verify the material quality of each Aluminum Gas Cylinder. Combined with automatic shaping machinery, this ensures precise cylinder interfaces and enhanced safety. The result is a lightweight, robust cylinder that paintball players can rely on for consistent performance, whether in recreational or competitive settings.

Premium Aluminum Gas Cylinders for Paintball

Shining Packaging’s paintball cylinders are designed with player needs in mind. Their lightweight construction improves maneuverability, while the high-quality aluminium alloy 6061-T6 guarantees long-term durability. With a typical delivery time of 30-40 days depending on order quantity, we ensure timely supply for B2B clients, including paintball equipment suppliers and tournament organizers. Contact us today to discuss your specifications and elevate your paintball experience with our premium cylinders.

Aluminum Cylinders Size

DOT 3AL Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 50 | 1.97 | 250 | 3625 | 417 | 6042 | 0.26 | 0.46 | 0.57 | 1.01 | DOT | DOT 3AL | DOT |

| 2 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.35 | 0.65 | 0.77 | 1.43 | DOT | UN ISO7866 | DOT |

| 3 | 61 | 2.40 | 207 | 3000 | 345 | 5000 | 0.4 | 0.7 | 0.88 | 1.54 | DOT | DOT 3AL | DOT |

| 4 | 73.8 | 2.91 | 160 | 2321 | 200 | 2901 | 0.62 | 0.62 | 1.36 | 1.36 | DOT | DOT 39 | DOT |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 6 | 73.8 | 2.91 | 150 | 2176 | 225 | 3263 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 7 | 81.5 | 3.21 | 153 | 2216 | 255 | 3694 | 0.6 | 1.3 | 1.32 | 2.87 | DOT | DOT 3AL | DOT |

| 8 | 81.5 | 3.21 | 124 | 1800 | 207 | 3000 | 0.63 | 1.17 | 1.39 | 2.58 | DOT | DOT 3AL | DOT |

| 9 | 90 | 3.54 | 207 | 3000 | 345 | 5000 | 0.92 | 1.68 | 2.03 | 3.70 | DOT | DOT 3AL | DOT |

| 10 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 1.2 | 2 | 2.65 | 4.41 | DOT | DOT 3AL | DOT |

| 11 | 111.3 | 4.38 | 124 | 1800 | 207 | 3000 | 0.98 | 1.82 | 2.16 | 4.01 | DOT | DOT 3AL | DOT |

| 12 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 2.52 | 4.68 | 5.56 | 10.32 | DOT | DOT 3AL | DOT |

| 13 | 133.4 | 5.25 | 153 | 2216 | 255 | 3694 | 3.9 | 7 | 8.60 | 15.43 | DOT | DOT 3AL | DOT |

| 14 | 133.4 | 5.25 | 124 | 1800 | 207 | 3000 | 2.38 | 4.42 | 5.25 | 9.74 | DOT | DOT 3AL | DOT |

TPED EN ISO7866 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.4 | 0.67 | 0.88 | 1.48 | TPED | EN ISO7866 | TUV |

| 2 | 60.5 | 2.38 | 200 | 2901 | 300 | 4351 | 0.35 | 0.7 | 0.77 | 1.54 | TPED | EN ISO7866 | TUV |

| 3 | 80 | 3.15 | 32 | 464 | 48 | 696 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TI |

| 4 | 70 | 2.76 | 120 | 1740 | 180 | 2611 | 0.2 | 1.2 | 0.44 | 2.65 | TPED | EN ISO11118 | TUV |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.3 | 0.44 | 2.87 | TPED | EN ISO11118 | TUV |

| 6 | 81.5 | 3.21 | 124 | 1798 | 186 | 2698 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TUV |

| 7 | 90 | 3.54 | 200 | 2901 | 300 | 4351 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 8 | 90 | 3.54 | 166 | 2408 | 250 | 3626 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 9 | 111 | 4.37 | 124 | 1798 | 186 | 2698 | 1.4 | 3.9 | 3.09 | 8.60 | TPED | EN ISO7866 | TUV |

| 10 | 111 | 4.37 | 200 | 2901 | 300 | 4351 | 1.4 | 4 | 3.09 | 8.82 | TPED | EN ISO7866 | TUV |

| 11 | 120 | 4.72 | 166 | 2408 | 250 | 3626 | 1.4 | 4.5 | 3.09 | 9.92 | TPED | EN ISO7866 | TUV |

| 12 | 140 | 5.51 | 166 | 2408 | 250 | 3626 | 4 | 8 | 8.82 | 17.64 | TPED | EN ISO7866 | TUV |

| 13 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TPED | EN ISO7866 | TUV |

| 14 | 184 | 7.24 | 166 | 2408 | 250 | 3626 | 6 | 15 | 13.23 | 33.07 | TPED | EN ISO7866 | TUV |

| 15 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 16 | 13.23 | 35.27 | TPED | EN ISO7866 | TUV |

| 16 | 203 | 7.99 | 166 | 2408 | 250 | 3626 | 11 | 20 | 24.25 | 44.09 | TPED | EN ISO7866 | TUV |

GB/T 11640 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test Pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 150 | 2176 | 225 | 3263 | 0.2 | 0.6 | 0.44 | 1.32 | TS | GB/T 11640 | TS |

| 2 | 60 | 2.36 | 300 | 4351 | 450 | 6527 | 0.2 | 0.5 | 0.44 | 1.10 | TS | GB/T 11640 | TS |

| 3 | 81.5 | 3.21 | 150 | 2176 | 225 | 3263 | 0.7 | 1.5 | 1.54 | 3.31 | TS | GB/T 11640 | TS |

| 4 | 111.3 | 4.38 | 200 | 2901 | 300 | 4351 | 1.1 | 4 | 2.43 | 8.82 | TS | GB/T 11640 | TS |

| 5 | 140 | 5.51 | 150 | 2176 | 225 | 3263 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 6 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 7 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 15 | 13.23 | 33.07 | TS | GB/T 11640 | TS |

| 8 | 203 | 7.99 | 150 | 2176 | 225 | 3263 | 8 | 20 | 17.64 | 44.09 | TS | GB/T 11640 | TS |

Production Process

At Shining Packaging, we deliver top-tier aluminum Paintball cylinders with unmatched precision and quality. Our state-of-the-art process includes: