Aluminum Scuba Tank 80cf AL80 Cylinder

Standard

DOT, TPED, GB/T

Material

Aluminium alloy 6061-T6

Applications

SCUBA

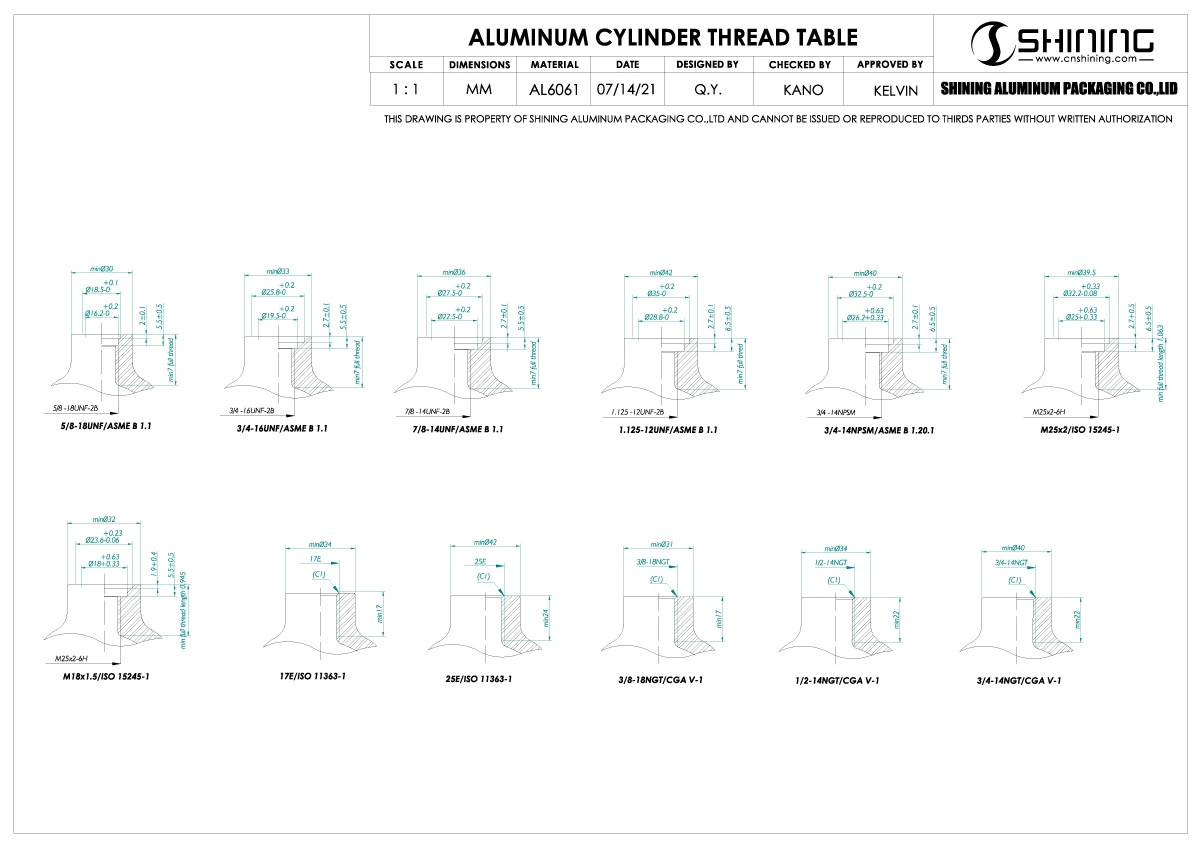

Valve & Thread

Specified & Installed Upon Request

Size

Custom Size is available with the TPED/DOT Certified Range

Finish

Unpainted & Brushed & Different Color Coated

Cleaning

Food Grade Cleaning by Ultrasonic Cleaners

Delivery Time

Usually 30-40 days Upon Quantity

Why Choose Our Aluminum Gas Cylinders?

At Shining Packaging, we specialize in crafting high-performance aluminum gas cylinders designed for scuba diving and other demanding applications. Our cylinders, made from premium aluminium alloy 6061-T6, meet stringent DOT, TPED, and GB/T standards, ensuring safety and reliability for professional and recreational divers. With a focus on quality, customization, and innovation, our products deliver unmatched durability and performance underwater.

Lightweight and Durable Design

Our aluminum gas cylinders are engineered to be lightweight, making them ideal for scuba divers seeking ease of transport and enhanced manoeuvrability during dives. Crafted from aluminium alloy 6061-T6, these cylinders offer exceptional strength without compromising on weight. This ensures a comfortable and dependable diving experience, whether you’re exploring coral reefs or deep-sea wrecks.

Superior Corrosion Resistance

Dive with confidence knowing our aluminum gas cylinders are highly resistant to corrosion. This feature extends the lifespan of your scuba equipment, protecting it from the harsh marine environment. Unlike traditional steel cylinders, our aluminium cylinders maintain their integrity over time, reducing maintenance costs and ensuring long-term reliability.

Customizable Sizes and Finishes

We offer tailored solutions to meet your specific needs. Our aluminum gas cylinders come in custom sizes within the DOT and TPED certified range, allowing you to choose the perfect fit for your diving requirements. Additionally, we provide a variety of surface finishes, including unpainted, brushed, or color-coated options, as well as polishing and body painting for a personalized look.

Advanced Manufacturing and Cleaning

Our state-of-the-art automatic shaping machinery ensures precise cylinder interfaces, enhancing safety and performance. Every aluminum gas cylinder undergoes rigorous food-grade cleaning using ultrasonic cleaners with 70°C pristine water, making them suitable for applications beyond scuba, such as the food and beverage industry. This meticulous process guarantees a clean and safe product for all users.

Custom Valves and Fast Delivery

We offer specified valves and thread installations upon request, ensuring compatibility with your scuba diving gear. With a typical delivery time of 30-40 days depending on order quantity, Shining Packaging ensures your aluminum gas cylinders arrive promptly, ready to support your next underwater adventure.

High-Quality Aluminum Gas Cylinders for Scuba Diving

Ready to elevate your diving experience? Shining Packaging is your trusted partner for premium aluminum gas cylinders. Contact us today to discuss your customization needs or request technical specifications. Dive deeper, safer, and smarter with our industry-leading solutions.

Aluminum Cylinders Size

DOT 3AL Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 50 | 1.97 | 250 | 3625 | 417 | 6042 | 0.26 | 0.46 | 0.57 | 1.01 | DOT | DOT 3AL | DOT |

| 2 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.35 | 0.65 | 0.77 | 1.43 | DOT | UN ISO7866 | DOT |

| 3 | 61 | 2.40 | 207 | 3000 | 345 | 5000 | 0.4 | 0.7 | 0.88 | 1.54 | DOT | DOT 3AL | DOT |

| 4 | 73.8 | 2.91 | 160 | 2321 | 200 | 2901 | 0.62 | 0.62 | 1.36 | 1.36 | DOT | DOT 39 | DOT |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 6 | 73.8 | 2.91 | 150 | 2176 | 225 | 3263 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 7 | 81.5 | 3.21 | 153 | 2216 | 255 | 3694 | 0.6 | 1.3 | 1.32 | 2.87 | DOT | DOT 3AL | DOT |

| 8 | 81.5 | 3.21 | 124 | 1800 | 207 | 3000 | 0.63 | 1.17 | 1.39 | 2.58 | DOT | DOT 3AL | DOT |

| 9 | 90 | 3.54 | 207 | 3000 | 345 | 5000 | 0.92 | 1.68 | 2.03 | 3.70 | DOT | DOT 3AL | DOT |

| 10 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 1.2 | 2 | 2.65 | 4.41 | DOT | DOT 3AL | DOT |

| 11 | 111.3 | 4.38 | 124 | 1800 | 207 | 3000 | 0.98 | 1.82 | 2.16 | 4.01 | DOT | DOT 3AL | DOT |

| 12 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 2.52 | 4.68 | 5.56 | 10.32 | DOT | DOT 3AL | DOT |

| 13 | 133.4 | 5.25 | 153 | 2216 | 255 | 3694 | 3.9 | 7 | 8.60 | 15.43 | DOT | DOT 3AL | DOT |

| 14 | 133.4 | 5.25 | 124 | 1800 | 207 | 3000 | 2.38 | 4.42 | 5.25 | 9.74 | DOT | DOT 3AL | DOT |

TPED EN ISO7866 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.4 | 0.67 | 0.88 | 1.48 | TPED | EN ISO7866 | TUV |

| 2 | 60.5 | 2.38 | 200 | 2901 | 300 | 4351 | 0.35 | 0.7 | 0.77 | 1.54 | TPED | EN ISO7866 | TUV |

| 3 | 80 | 3.15 | 32 | 464 | 48 | 696 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TI |

| 4 | 70 | 2.76 | 120 | 1740 | 180 | 2611 | 0.2 | 1.2 | 0.44 | 2.65 | TPED | EN ISO11118 | TUV |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.3 | 0.44 | 2.87 | TPED | EN ISO11118 | TUV |

| 6 | 81.5 | 3.21 | 124 | 1798 | 186 | 2698 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TUV |

| 7 | 90 | 3.54 | 200 | 2901 | 300 | 4351 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 8 | 90 | 3.54 | 166 | 2408 | 250 | 3626 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 9 | 111 | 4.37 | 124 | 1798 | 186 | 2698 | 1.4 | 3.9 | 3.09 | 8.60 | TPED | EN ISO7866 | TUV |

| 10 | 111 | 4.37 | 200 | 2901 | 300 | 4351 | 1.4 | 4 | 3.09 | 8.82 | TPED | EN ISO7866 | TUV |

| 11 | 120 | 4.72 | 166 | 2408 | 250 | 3626 | 1.4 | 4.5 | 3.09 | 9.92 | TPED | EN ISO7866 | TUV |

| 12 | 140 | 5.51 | 166 | 2408 | 250 | 3626 | 4 | 8 | 8.82 | 17.64 | TPED | EN ISO7866 | TUV |

| 13 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TPED | EN ISO7866 | TUV |

| 14 | 184 | 7.24 | 166 | 2408 | 250 | 3626 | 6 | 15 | 13.23 | 33.07 | TPED | EN ISO7866 | TUV |

| 15 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 16 | 13.23 | 35.27 | TPED | EN ISO7866 | TUV |

| 16 | 203 | 7.99 | 166 | 2408 | 250 | 3626 | 11 | 20 | 24.25 | 44.09 | TPED | EN ISO7866 | TUV |

GB/T 11640 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test Pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 150 | 2176 | 225 | 3263 | 0.2 | 0.6 | 0.44 | 1.32 | TS | GB/T 11640 | TS |

| 2 | 60 | 2.36 | 300 | 4351 | 450 | 6527 | 0.2 | 0.5 | 0.44 | 1.10 | TS | GB/T 11640 | TS |

| 3 | 81.5 | 3.21 | 150 | 2176 | 225 | 3263 | 0.7 | 1.5 | 1.54 | 3.31 | TS | GB/T 11640 | TS |

| 4 | 111.3 | 4.38 | 200 | 2901 | 300 | 4351 | 1.1 | 4 | 2.43 | 8.82 | TS | GB/T 11640 | TS |

| 5 | 140 | 5.51 | 150 | 2176 | 225 | 3263 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 6 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 7 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 15 | 13.23 | 33.07 | TS | GB/T 11640 | TS |

| 8 | 203 | 7.99 | 150 | 2176 | 225 | 3263 | 8 | 20 | 17.64 | 44.09 | TS | GB/T 11640 | TS |

Production Process

At Shining Packaging, we deliver top-tier aluminum SCUBA cylinders with unmatched precision and quality. Our state-of-the-art process includes: