Aluminum Industrial Gas Cylinder 6061 DOT

Standard

DOT, TPED, GB/T

Material

Aluminium alloy 6061-T6

Applications

Highly volatile, exotic, and speciality gases for industrial uses

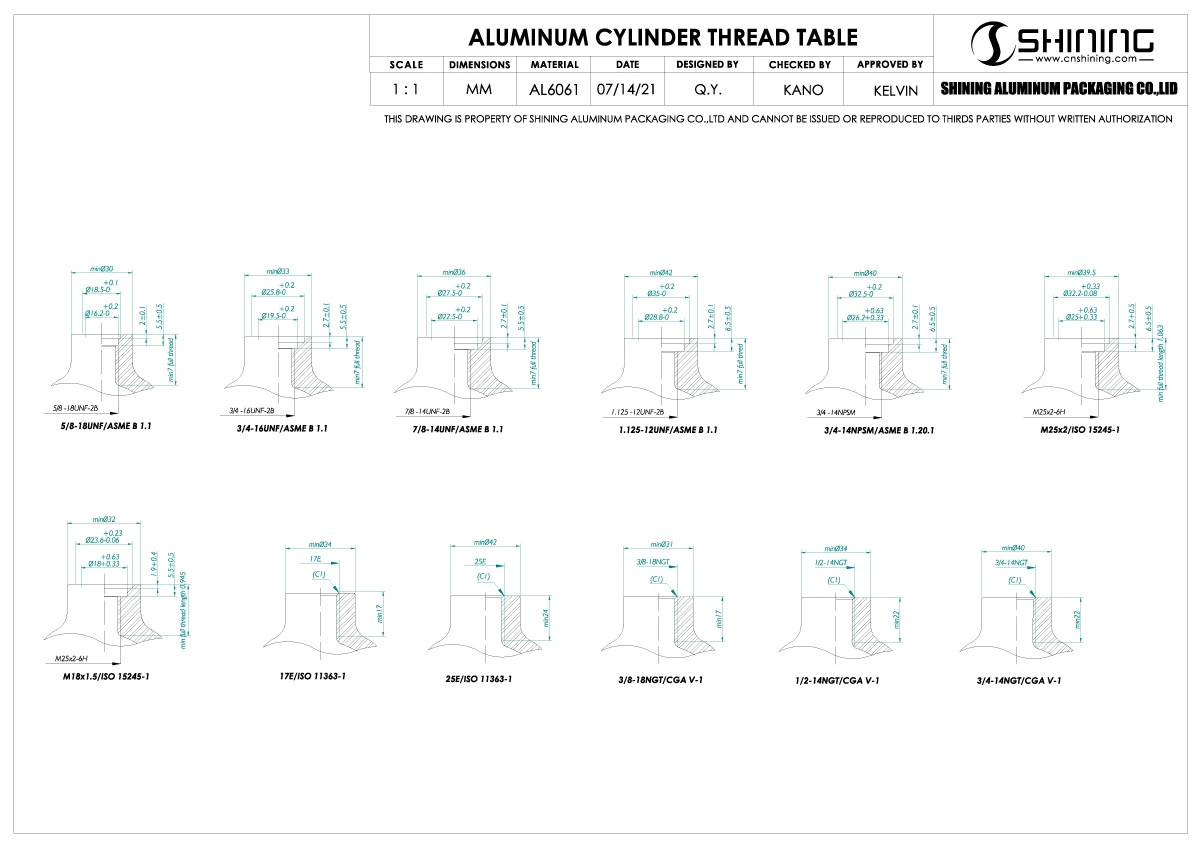

Valve & Thread

Specified & Installed Upon Request

Size

Custom Size is available with the TPED/DOT Certified Range

Finish

Unpainted & Brushed & Different Color Coated

Delivery Time

Usually 30-40 days Upon Quantity

Why Choose Our Aluminum Gas Cylinders?

Shining Packaging specializes in delivering top-tier Aluminum Gas Cylinders designed for specialty and industrial applications. Crafted from high-grade aluminum alloy 6061-T6, our cylinders meet rigorous standards like DOT, TPED, and GB/T, ensuring reliability and safety across diverse industries. With customizable sizes, finishes, and valve options, our products are tailored to meet your specific needs.

Key Features of Aluminum Gas Cylinders

Our Aluminum Gas Cylinders are engineered for exceptional performance. Their lightweight durability makes them easy to transport while maintaining structural integrity in demanding environments. The corrosion resistance of aluminum ensures long-term reliability, ideal for marine and offshore applications. Additionally, their high thermal conductivity supports efficient heat dissipation, reducing risks during gas storage and transport.

With options for custom sizes within the TPED/DOT certified range, and finishes like unpainted, brushed, or color-coated, our cylinders offer flexibility and aesthetic appeal. Valves and threads are specified and installed upon request, ensuring compatibility with your systems.

Applications in Specialty & Industrial Sectors

Our Aluminum Gas Cylinders serve a wide range of industries. In medical and healthcare, they store critical gases like oxygen and nitrogen for hospitals and emergencies. For welding and cutting, they ensure safe storage of gases like acetylene and argon. Laboratories rely on our cylinders for specialty gases used in research, while the aerospace sector uses them for propulsion and life support systems. In industrial manufacturing, our cylinders support processes in automotive, electronics, and more.

Eco-Friendly and Versatile Solutions

Choosing our Aluminum Gas Cylinders aligns with sustainable practices. Made from recyclable aluminum alloy, they are an eco-friendly choice for environmentally conscious businesses. Their ability to allow visual inspection simplifies gas level monitoring, enhancing operational efficiency. Whether for highly volatile gases or exotic gases, our cylinders deliver unmatched reliability.

High-Quality Aluminum Gas Cylinders

At Shining Packaging, we prioritize efficiency. Our Aluminum Gas Cylinders are delivered in 30-40 days, depending on order quantity. With custom size options and tailored valve installations, we ensure your cylinders meet exact specifications for your specialty or industrial applications.

Aluminum Cylinders Size

DOT 3AL Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 50 | 1.97 | 250 | 3625 | 417 | 6042 | 0.26 | 0.46 | 0.57 | 1.01 | DOT | DOT 3AL | DOT |

| 2 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.35 | 0.65 | 0.77 | 1.43 | DOT | UN ISO7866 | DOT |

| 3 | 61 | 2.40 | 207 | 3000 | 345 | 5000 | 0.4 | 0.7 | 0.88 | 1.54 | DOT | DOT 3AL | DOT |

| 4 | 73.8 | 2.91 | 160 | 2321 | 200 | 2901 | 0.62 | 0.62 | 1.36 | 1.36 | DOT | DOT 39 | DOT |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 6 | 73.8 | 2.91 | 150 | 2176 | 225 | 3263 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 7 | 81.5 | 3.21 | 153 | 2216 | 255 | 3694 | 0.6 | 1.3 | 1.32 | 2.87 | DOT | DOT 3AL | DOT |

| 8 | 81.5 | 3.21 | 124 | 1800 | 207 | 3000 | 0.63 | 1.17 | 1.39 | 2.58 | DOT | DOT 3AL | DOT |

| 9 | 90 | 3.54 | 207 | 3000 | 345 | 5000 | 0.92 | 1.68 | 2.03 | 3.70 | DOT | DOT 3AL | DOT |

| 10 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 1.2 | 2 | 2.65 | 4.41 | DOT | DOT 3AL | DOT |

| 11 | 111.3 | 4.38 | 124 | 1800 | 207 | 3000 | 0.98 | 1.82 | 2.16 | 4.01 | DOT | DOT 3AL | DOT |

| 12 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 2.52 | 4.68 | 5.56 | 10.32 | DOT | DOT 3AL | DOT |

| 13 | 133.4 | 5.25 | 153 | 2216 | 255 | 3694 | 3.9 | 7 | 8.60 | 15.43 | DOT | DOT 3AL | DOT |

| 14 | 133.4 | 5.25 | 124 | 1800 | 207 | 3000 | 2.38 | 4.42 | 5.25 | 9.74 | DOT | DOT 3AL | DOT |

TPED EN ISO7866 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.4 | 0.67 | 0.88 | 1.48 | TPED | EN ISO7866 | TUV |

| 2 | 60.5 | 2.38 | 200 | 2901 | 300 | 4351 | 0.35 | 0.7 | 0.77 | 1.54 | TPED | EN ISO7866 | TUV |

| 3 | 80 | 3.15 | 32 | 464 | 48 | 696 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TI |

| 4 | 70 | 2.76 | 120 | 1740 | 180 | 2611 | 0.2 | 1.2 | 0.44 | 2.65 | TPED | EN ISO11118 | TUV |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.3 | 0.44 | 2.87 | TPED | EN ISO11118 | TUV |

| 6 | 81.5 | 3.21 | 124 | 1798 | 186 | 2698 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TUV |

| 7 | 90 | 3.54 | 200 | 2901 | 300 | 4351 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 8 | 90 | 3.54 | 166 | 2408 | 250 | 3626 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 9 | 111 | 4.37 | 124 | 1798 | 186 | 2698 | 1.4 | 3.9 | 3.09 | 8.60 | TPED | EN ISO7866 | TUV |

| 10 | 111 | 4.37 | 200 | 2901 | 300 | 4351 | 1.4 | 4 | 3.09 | 8.82 | TPED | EN ISO7866 | TUV |

| 11 | 120 | 4.72 | 166 | 2408 | 250 | 3626 | 1.4 | 4.5 | 3.09 | 9.92 | TPED | EN ISO7866 | TUV |

| 12 | 140 | 5.51 | 166 | 2408 | 250 | 3626 | 4 | 8 | 8.82 | 17.64 | TPED | EN ISO7866 | TUV |

| 13 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TPED | EN ISO7866 | TUV |

| 14 | 184 | 7.24 | 166 | 2408 | 250 | 3626 | 6 | 15 | 13.23 | 33.07 | TPED | EN ISO7866 | TUV |

| 15 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 16 | 13.23 | 35.27 | TPED | EN ISO7866 | TUV |

| 16 | 203 | 7.99 | 166 | 2408 | 250 | 3626 | 11 | 20 | 24.25 | 44.09 | TPED | EN ISO7866 | TUV |

GB/T 11640 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test Pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 150 | 2176 | 225 | 3263 | 0.2 | 0.6 | 0.44 | 1.32 | TS | GB/T 11640 | TS |

| 2 | 60 | 2.36 | 300 | 4351 | 450 | 6527 | 0.2 | 0.5 | 0.44 | 1.10 | TS | GB/T 11640 | TS |

| 3 | 81.5 | 3.21 | 150 | 2176 | 225 | 3263 | 0.7 | 1.5 | 1.54 | 3.31 | TS | GB/T 11640 | TS |

| 4 | 111.3 | 4.38 | 200 | 2901 | 300 | 4351 | 1.1 | 4 | 2.43 | 8.82 | TS | GB/T 11640 | TS |

| 5 | 140 | 5.51 | 150 | 2176 | 225 | 3263 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 6 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 7 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 15 | 13.23 | 33.07 | TS | GB/T 11640 | TS |

| 8 | 203 | 7.99 | 150 | 2176 | 225 | 3263 | 8 | 20 | 17.64 | 44.09 | TS | GB/T 11640 | TS |

Production Process

At Shining Packaging, we deliver top-tier aluminum gas cylinders with unmatched precision and quality. Our state-of-the-art process includes: