Aluminum Medical Oxygen Cylinder M6 M9

Standard

DOT, TPED, GB/T

Material

Aluminium alloy 6061-T6

Applications

Medical Oxygen

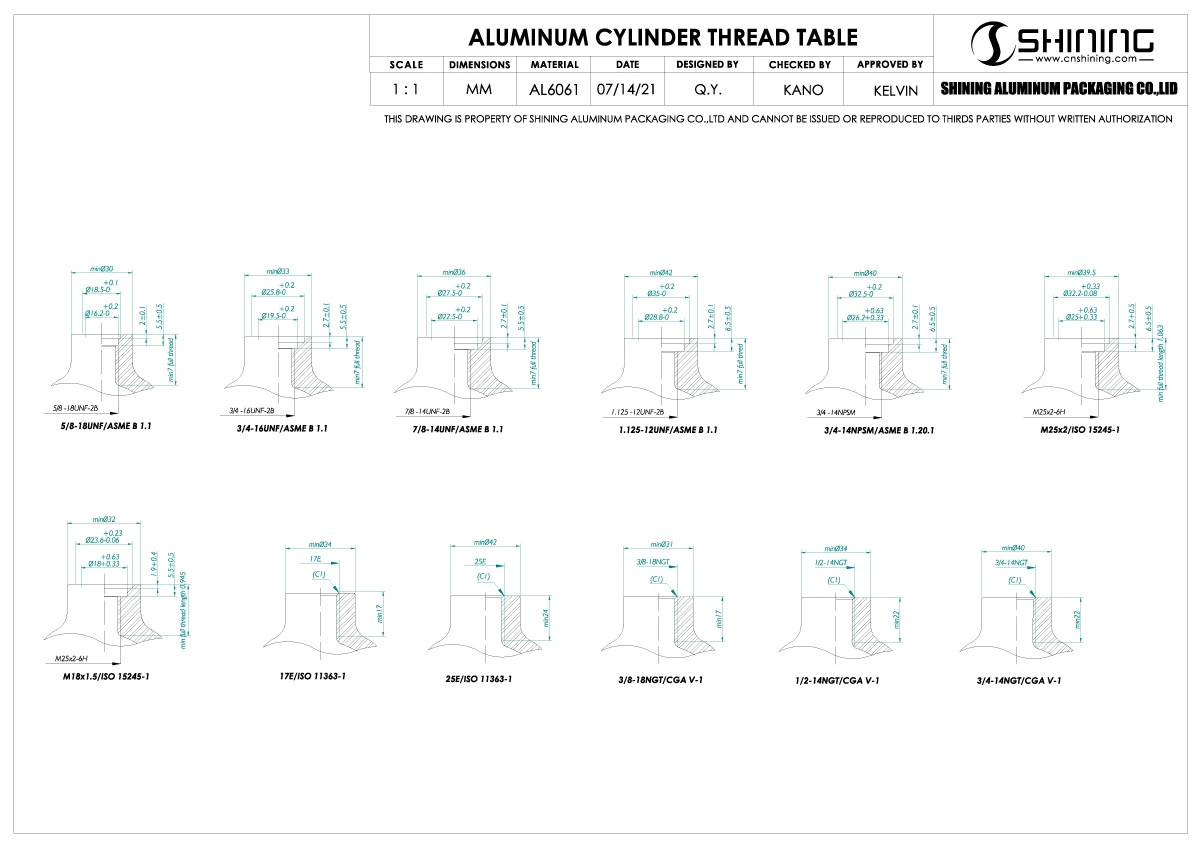

Valve & Thread

Specified & Installed Upon Request

Size

Custom Size is available with the TPED/DOT Certified Range

Finish

Unpainted & Brushed & Different Color Coated

Cleaning

Food Grade Cleaning by Ultrasonic Cleaners

Delivery Time

Usually 30-40 days Upon Quantity

Why Choose Our Aluminum Gas Cylinders?

At Shining Packaging, we specialize in manufacturing high-quality aluminum gas cylinders designed for medical and industrial applications. Crafted from premium aluminum alloy 6061-T6, our cylinders are lightweight, durable, and corrosion-resistant, making them ideal for storing and transporting medical oxygen. Compliant with international standards such as DOT, TPED, and GB/T, our products ensure safety and reliability for B2B clients worldwide.

Customizable Aluminum Oxygen Cylinders

Our aluminum oxygen cylinders are tailored to meet diverse needs. Available in custom sizes within the TPED/DOT-certified range, they come with specified valves and threads installed upon request. Whether you need cylinders for emergency medical services or chronic respiratory care, our products offer flexibility and precision to suit your requirements.

Superior Finish and Cleaning Standards

Shining Packaging ensures every aluminum gas cylinder meets the highest quality standards. Choose from unpainted, brushed, or various color-coated finishes to match your branding or operational needs. Our cylinders undergo rigorous food-grade cleaning using ultrasonic cleaners, ensuring they are safe for medical oxygen applications.

Reliable Delivery for B2B Clients

We understand the importance of timely delivery for businesses. Shining Packaging guarantees a standard delivery time of 30-40 days, depending on order quantity. Our efficient production and logistics processes ensure your aluminum oxygen cylinders arrive when you need them, supporting seamless operations for hospitals, clinics, and medical suppliers.

Premium Aluminum Gas Cylinders for Medical Use

Our cylinders are widely used in medical oxygen supply for hospitals, emergency response teams, and home healthcare. Their lightweight design makes them easy to transport, while their robust construction ensures long-term durability. Trust Shining Packaging for aluminum gas cylinders that deliver oxygen, the elixir of life, safely and efficiently.

Aluminum Cylinders Size

DOT 3AL Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 50 | 1.97 | 250 | 3625 | 417 | 6042 | 0.26 | 0.46 | 0.57 | 1.01 | DOT | DOT 3AL | DOT |

| 2 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.35 | 0.65 | 0.77 | 1.43 | DOT | UN ISO7866 | DOT |

| 3 | 61 | 2.40 | 207 | 3000 | 345 | 5000 | 0.4 | 0.7 | 0.88 | 1.54 | DOT | DOT 3AL | DOT |

| 4 | 73.8 | 2.91 | 160 | 2321 | 200 | 2901 | 0.62 | 0.62 | 1.36 | 1.36 | DOT | DOT 39 | DOT |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 6 | 73.8 | 2.91 | 150 | 2176 | 225 | 3263 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 7 | 81.5 | 3.21 | 153 | 2216 | 255 | 3694 | 0.6 | 1.3 | 1.32 | 2.87 | DOT | DOT 3AL | DOT |

| 8 | 81.5 | 3.21 | 124 | 1800 | 207 | 3000 | 0.63 | 1.17 | 1.39 | 2.58 | DOT | DOT 3AL | DOT |

| 9 | 90 | 3.54 | 207 | 3000 | 345 | 5000 | 0.92 | 1.68 | 2.03 | 3.70 | DOT | DOT 3AL | DOT |

| 10 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 1.2 | 2 | 2.65 | 4.41 | DOT | DOT 3AL | DOT |

| 11 | 111.3 | 4.38 | 124 | 1800 | 207 | 3000 | 0.98 | 1.82 | 2.16 | 4.01 | DOT | DOT 3AL | DOT |

| 12 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 2.52 | 4.68 | 5.56 | 10.32 | DOT | DOT 3AL | DOT |

| 13 | 133.4 | 5.25 | 153 | 2216 | 255 | 3694 | 3.9 | 7 | 8.60 | 15.43 | DOT | DOT 3AL | DOT |

| 14 | 133.4 | 5.25 | 124 | 1800 | 207 | 3000 | 2.38 | 4.42 | 5.25 | 9.74 | DOT | DOT 3AL | DOT |

TPED EN ISO7866 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.4 | 0.67 | 0.88 | 1.48 | TPED | EN ISO7866 | TUV |

| 2 | 60.5 | 2.38 | 200 | 2901 | 300 | 4351 | 0.35 | 0.7 | 0.77 | 1.54 | TPED | EN ISO7866 | TUV |

| 3 | 80 | 3.15 | 32 | 464 | 48 | 696 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TI |

| 4 | 70 | 2.76 | 120 | 1740 | 180 | 2611 | 0.2 | 1.2 | 0.44 | 2.65 | TPED | EN ISO11118 | TUV |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.3 | 0.44 | 2.87 | TPED | EN ISO11118 | TUV |

| 6 | 81.5 | 3.21 | 124 | 1798 | 186 | 2698 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TUV |

| 7 | 90 | 3.54 | 200 | 2901 | 300 | 4351 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 8 | 90 | 3.54 | 166 | 2408 | 250 | 3626 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 9 | 111 | 4.37 | 124 | 1798 | 186 | 2698 | 1.4 | 3.9 | 3.09 | 8.60 | TPED | EN ISO7866 | TUV |

| 10 | 111 | 4.37 | 200 | 2901 | 300 | 4351 | 1.4 | 4 | 3.09 | 8.82 | TPED | EN ISO7866 | TUV |

| 11 | 120 | 4.72 | 166 | 2408 | 250 | 3626 | 1.4 | 4.5 | 3.09 | 9.92 | TPED | EN ISO7866 | TUV |

| 12 | 140 | 5.51 | 166 | 2408 | 250 | 3626 | 4 | 8 | 8.82 | 17.64 | TPED | EN ISO7866 | TUV |

| 13 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TPED | EN ISO7866 | TUV |

| 14 | 184 | 7.24 | 166 | 2408 | 250 | 3626 | 6 | 15 | 13.23 | 33.07 | TPED | EN ISO7866 | TUV |

| 15 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 16 | 13.23 | 35.27 | TPED | EN ISO7866 | TUV |

| 16 | 203 | 7.99 | 166 | 2408 | 250 | 3626 | 11 | 20 | 24.25 | 44.09 | TPED | EN ISO7866 | TUV |

GB/T 11640 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test Pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 150 | 2176 | 225 | 3263 | 0.2 | 0.6 | 0.44 | 1.32 | TS | GB/T 11640 | TS |

| 2 | 60 | 2.36 | 300 | 4351 | 450 | 6527 | 0.2 | 0.5 | 0.44 | 1.10 | TS | GB/T 11640 | TS |

| 3 | 81.5 | 3.21 | 150 | 2176 | 225 | 3263 | 0.7 | 1.5 | 1.54 | 3.31 | TS | GB/T 11640 | TS |

| 4 | 111.3 | 4.38 | 200 | 2901 | 300 | 4351 | 1.1 | 4 | 2.43 | 8.82 | TS | GB/T 11640 | TS |

| 5 | 140 | 5.51 | 150 | 2176 | 225 | 3263 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 6 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 7 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 15 | 13.23 | 33.07 | TS | GB/T 11640 | TS |

| 8 | 203 | 7.99 | 150 | 2176 | 225 | 3263 | 8 | 20 | 17.64 | 44.09 | TS | GB/T 11640 | TS |

Production Process

At Shining Packaging, we deliver top-tier aluminum gas cylinders with unmatched precision and quality. Our state-of-the-art process includes: