Standard Overview

The EN 14848:2018 standard defines the dimensional specifications for valve cups used in metal aerosol containers with 25.4 mm apertures. These measurements are essential to ensure proper sealing, alignment, and compatibility with clinching systems during the filling and sealing process.

This standard is closely related to EN 14847 (tinplate can aperture) and EN 15006 (aluminium containers), ensuring an integrated interface between can, valve cup, and actuator system.

1.Scope and Applicability

This standard applies to all aerosol valve cups used on containers with a nominal aperture of 25.4 mm. It is independent of the valve cup material—applicable to:

- Tinplate

- Blackplate

- Stainless steel

- Aluminium and alloys

Important: Dimples on the container aperture are not specified in this standard, as they may damage coatings or reduce seal integrity.

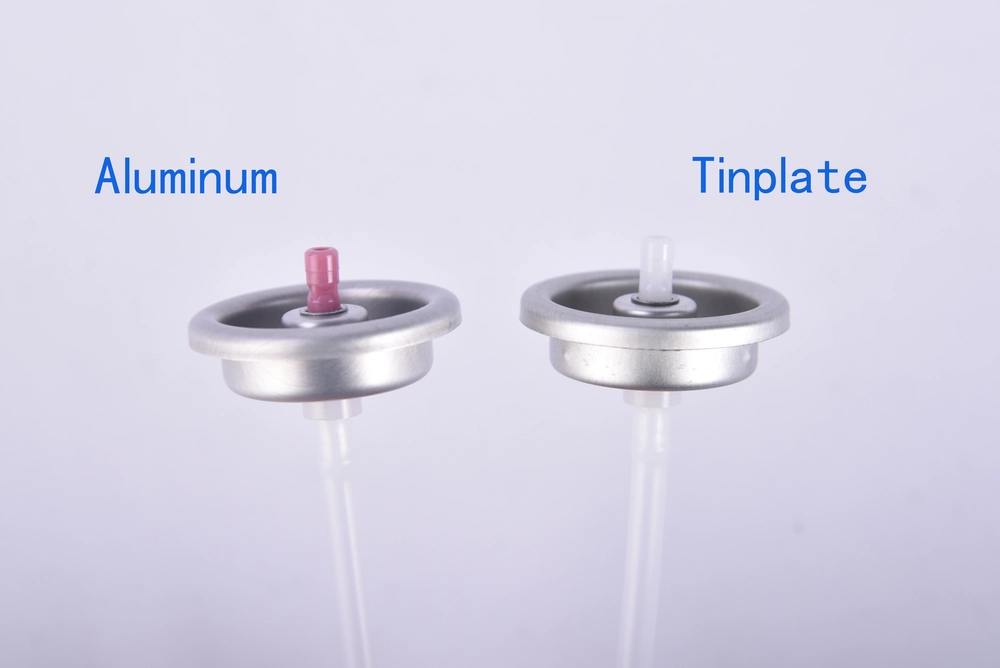

2.Valve Cup Types and Dimensions

The standard defines 3 common geometries of valve cups, represented in the diagram below. The critical dimensions are:

- S – Wall Thickness

- D – Outside Diameter of the cup

Table 1: Valve Cup Dimensions by Wall Thickness

| Wall Thickness (S) | Outside Diameter (D) |

|---|---|

| 0.25 mm | 32.50 ± 0.10 mm |

| 0.27 mm | 32.50 ± 0.10 mm |

| 0.28 mm | 32.50 ± 0.10 mm |

| 0.30 mm | 32.50 ± 0.10 mm |

| 0.40 mm | 32.50 ± 0.10 mm |

| 0.42 mm | 32.50 ± 0.10 mm |

| 0.50 mm | 32.90 ± 0.10 mm |

| 0.60 mm | 33.10 ± 0.10 mm |

3.Compatibility Considerations

- The cup body diameter may be less than 25.15 mm ± 0.08 mm if using plastic sleeve gaskets.

- Caution is advised during clinching to avoid approaching the cup base too closely, which may deform the wall or compromise the seal.

4.Practical Application

4.1 Filling Line Setup

Valve cups designed to EN 14848 ensure a consistent clinch interface, minimizing leakage risks during propellant injection and actuation testing.

4.2 Component Sourcing

Global compatibility with EN-compliant containers and caps makes sourcing from multiple suppliers easier and more predictable.

4.3 Material Flexibility

Standardization of dimensions allows substitution of tinplate with stainless or aluminum valve cups, maintaining the same assembly tooling.

Download the Standard PDF

This document provides EN 14848, defining critical dimensional requirements for valve cups used with 25.4 mm aperture metal aerosol containers. It supports reliable clinching performance, manufacturing control, and incoming inspection across aerosol packaging and filling operations.

FAQs – Valve Cup Dimensioning

No. EN 14848 applies exclusively to metal valve cups. However, metal cups using plastic sleeve gaskets are supported, provided the internal diameter is adjusted to maintain proper gasket compression.

EN 14847 defines the geometry of the aerosol can aperture. EN 14848 defines the valve cup that must fit into that aperture, making the two standards complementary and inseparable in practice.

Unlisted wall thicknesses require careful evaluation against the closest defined geometry. Using non-standard thicknesses without validation often leads to unpredictable clinch deformation and sealing variability.

Yes. EN 14848 applies exclusively to 25.4 mm (1 inch) aerosol systems. Other aperture sizes, such as 20 mm systems, are covered by separate EN or FEA standards.