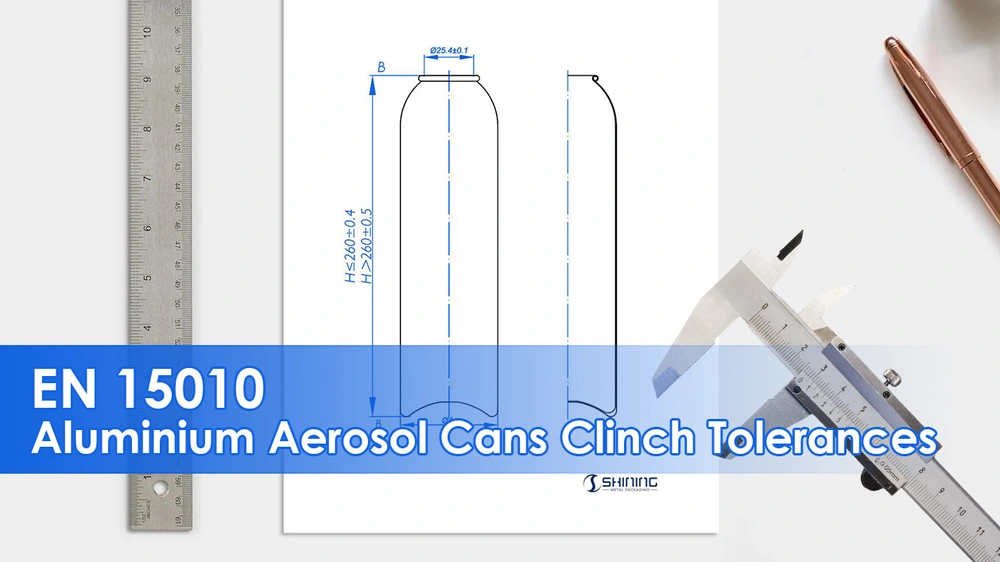

Standard Overview

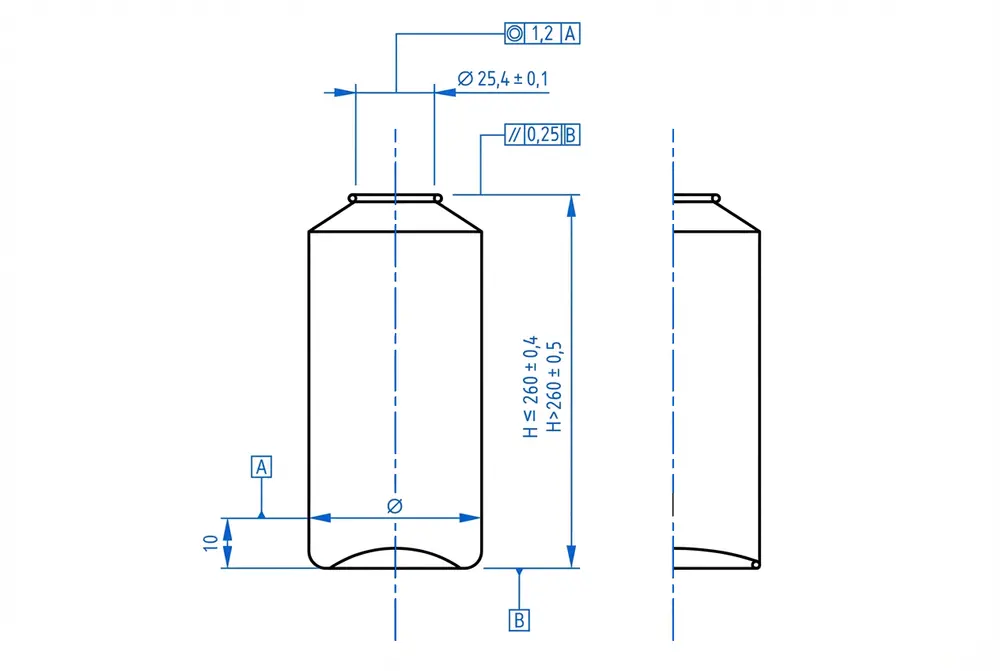

The EN 15010:2006 standard specifies the dimensional tolerances for aluminium aerosol containers with a 25.4 mm aperture when clinching with valve cups. These tolerances are crucial for ensuring effective sealing during manufacturing, as improper clinching can lead to leaks or failure in pressurization. The standard covers dimensions related to the aperture, parallelism, eccentricity, and height.

1. Role of EN 15010 in the Standards System

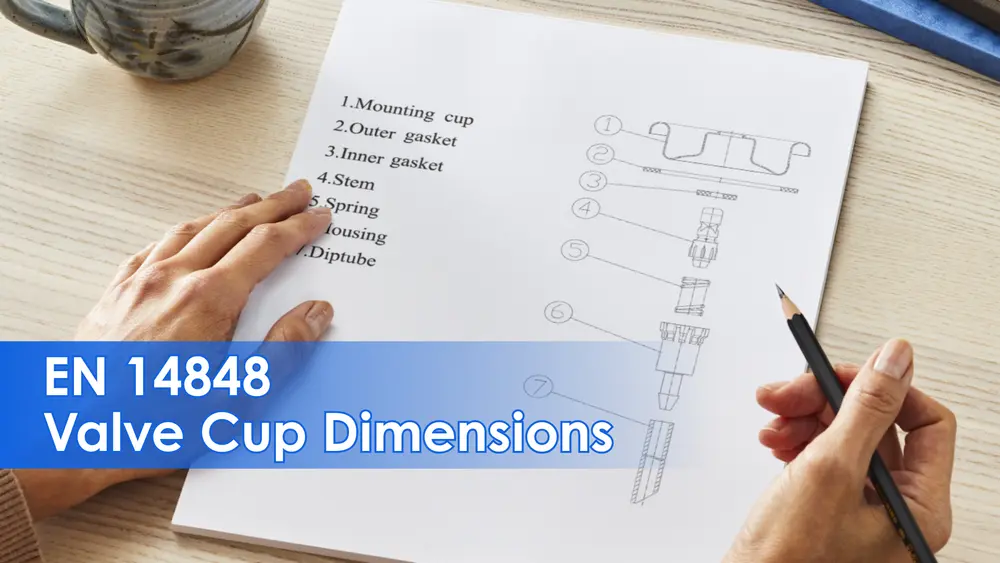

EN 15010 should always be applied together with:

- ISO 90-3 – capacity and height reference

- EN 14848 – valve cup geometry

- EN 15006 – aluminium can aperture dimensions

- EN 15008 – aluminium one-piece can dimensions

Together, these standards form a complete can–valve–clinch compatibility system.

2. Key Clinch-Related Tolerances

Eccentricity (A)

Eccentricity defines how far the aperture centerline is allowed to deviate from the can body axis. Excessive eccentricity causes uneven gasket compression during clinching.

Parallelism (B)

Parallelism controls the angular alignment between the aperture plane and the can base reference. Poor parallelism results in tilted valves and asymmetric clinch profiles.

Height Tolerance (H)

Height tolerance defines how much the vertical position of the aperture may vary relative to the can base. Different limits apply depending on overall can height.

| Overall Can Height | Height Tolerance |

|---|---|

| H ≤ 260 mm | ± 0.4 mm |

| H > 260 mm | ± 0.5 mm |

3. Impact on Sealing Efficiency and Interchangeability

The tolerances defined in EN 15010 are not purely geometric; they are functional limits derived from extensive industry experience.

When these tolerances are respected:

- Valve cups from different suppliers remain interchangeable

- Clinch force distribution is uniform

- Long-term leak performance is improved

When they are exceeded:

- Local gasket over-compression or under-compression occurs

- Valve tilt and cosmetic defects appear

- Delayed leakage becomes more likely

Download the Standard PDF

This document presents EN 15010, specifying tolerance requirements for fundamental dimensions of aluminium aerosol containers in relation to the clinch. It supports control of parallelism, eccentricity, and height, ensuring reliable valve clinching, manufacturing consistency, and quality assurance in aerosol packaging.

Frequently Asked Questions (FAQ)

EN 15010 defines clinch-related tolerances that complement aperture and container geometry standards. It works together with EN 15006, EN 15008, and EN 14848 to ensure full compatibility between aluminium cans, valve cups, and clinching tools.

Parallelism and eccentricity directly affect how evenly the valve cup and gasket are compressed during clinching. Exceeding these tolerances often leads to asymmetric seals, valve tilt, and increased risk of delayed leakage.

Yes. Taller cans are allowed slightly larger height tolerances due to forming and handling limitations. However, increased height variation requires careful adjustment of filling and clinching equipment to maintain sealing consistency.

Custom tooling may partially compensate for deviations, but it cannot fully correct fundamental geometric errors. Relying on tooling adjustments instead of compliant dimensions usually reduces interchangeability and process robustness.

The tolerances are not legally mandatory, but they represent proven industry best practice. In production environments, exceeding these limits is a common root cause of sealing instability and quality complaints.