Standard Overview

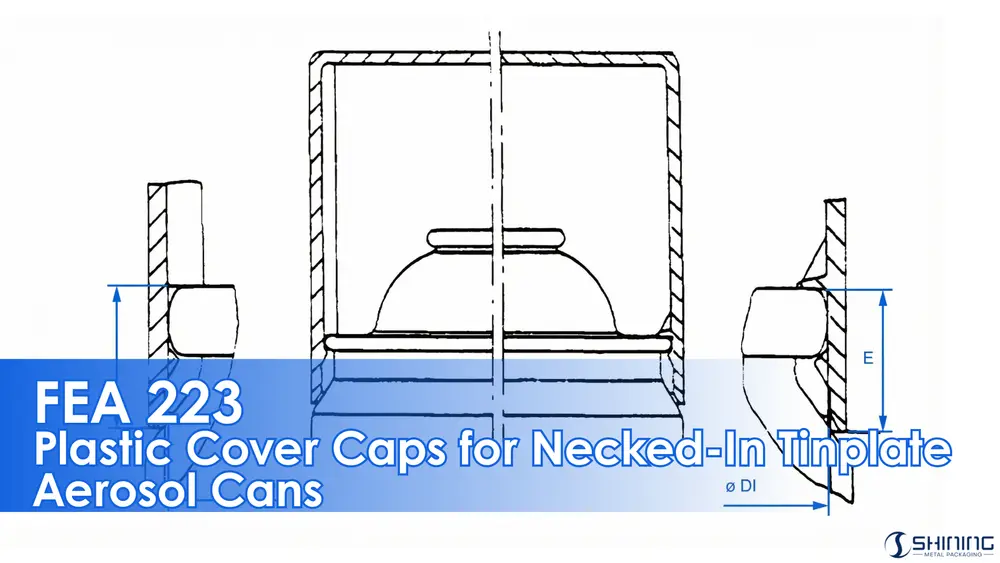

FEA 223 is a dimensional standard issued by the European Aerosol Federation (FEA), defining the critical dimensions of plastic cover caps used on two- and three-piece necked-in tinplate aerosol containers conforming to FEA 214.

Unlike valve or container standards, FEA 223 focuses on a downstream component that directly affects product protection, handling stability, and consumer safety.

1. Scope and Functional Role

FEA 223 applies to plastic cover caps and spray domes that function as protective caps on necked-in tinplate aerosol containers.

The standard ensures:

- Secure fit on container shoulders

- Avoidance of contact with valve actuators

- Sufficient clearance to absorb top-load forces

2. Key Dimensions Explained

The standard defines two functional dimensions:

- DI – internal diameter in the sector between dimples and supporting ribs

- E – maximum distance between the supporting ring/ribs and the cap bottom

2.1 Internal Diameter (DI)

DI ensures correct engagement with the container shoulder while avoiding excessive friction or deformation. It is measured in the functional sector between dimples and ribs rather than at the free edge.

2.2 Maximum Internal Height (E)

Dimension E defines the available vertical clearance above the valve and actuator. It prevents contact under compression or top-load conditions.

3. Dimensional Requirements

| Nominal Container Diameter D (mm) | Cap Internal Diameter DI (mm) | Maximum Distance E (mm) |

|---|---|---|

| 45 | 43.6 ± 0.20 | 5.7 |

| 49 | 47.8 ± 0.20 | 5.9 |

| 52 | 50.7 ± 0.20 | 6.0 |

| 57 | 55.5 ± 0.20 | 6.5 |

| 65 | 63.2 ± 0.20 | 6.8 |

4. Relationship with Other Standards

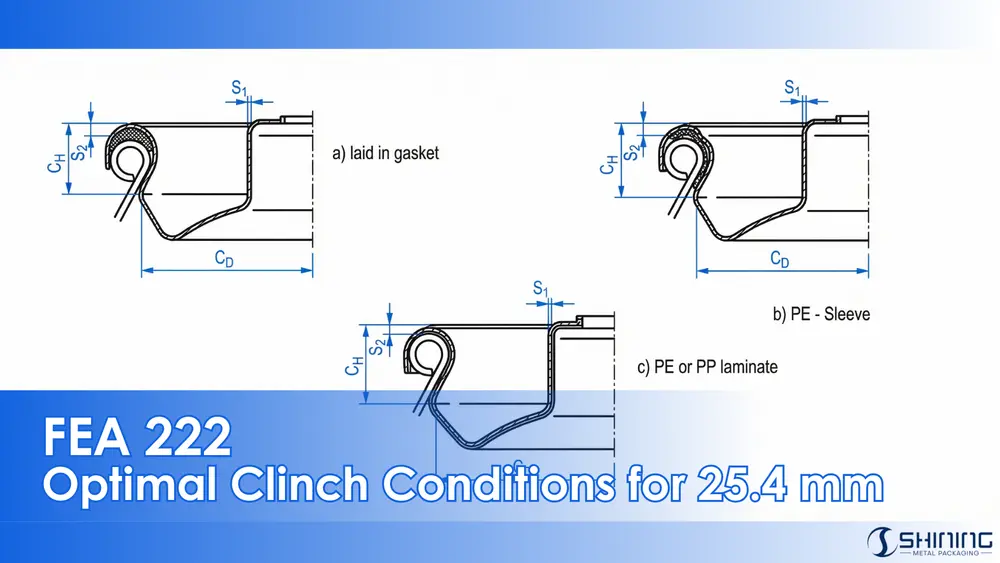

FEA 223 operates within a defined standards chain:

- EN15007 – defines the dimensions of necked-in tinplate containers

- EN 14847 – defines the 25.4 mm aperture

- EN 14848 – defines the valve cup geometry

- FEA 646 – evaluates top-load resistance of filled packs

Together, these standards ensure compatibility from container forming through filling, capping, and transport.

5. Practical Application Scenarios

5.1 Cap Manufacturing

FEA 223 provides stable dimensional targets for injection-molded caps with predictable snap-on behavior.

5.2 Filling and Packaging Lines

Standardized cap geometry reduces jamming, misalignment, and actuator interference on high-speed lines.

5.3 Procurement and Multi-Sourcing

Specifying FEA 223 allows caps from different suppliers to be used interchangeably on FEA 214 containers.

Download the Standard PDF

This document provides FEA 223, defining dimensional requirements for plastic cover caps used on two- and three-piece necked-in tinplate aerosol containers conforming to FEA 214. It specifies critical internal diameters and seating dimensions to ensure proper fit, protection, and functional compatibility.

FAQ – Engineering & Purchasing

No, but it represents established industry practice. Using non-standard caps significantly increases the risk of actuator interference and handling issues.

No. FEA 223 applies only to necked-in tinplate containers. Aluminium containers use different shoulder geometries and cap interfaces.

Yes, provided they function as protective cover caps and meet the same dimensional requirements. Functional behavior is more critical than naming.

The cap may contact the actuator under load. This can cause unintentional actuation, deformation, or loss of function during transport.

Yes, especially when sourcing caps and containers from different suppliers. It reduces fit-related complaints and line-side adjustments.