The global aerosol paint market, encompassing silver spray paint, was valued at approximately USD 2.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% through 2030, driven by demand in automotive refinishing and DIY home projects. Silver aerosol spray paint stands out for its metallic finish and user-friendly application, with social media platforms like Pinterest reporting a 20% surge in searches for “silver spray paint projects” in 2024. These insights highlight the growing popularity of silver aerosol paints across diverse applications. Source: Grand View Research.

This guide delves into the essentials of silver aerosol spray paint, exploring its composition, applications, and best practices for use. From technical specifications to safety tips, we aim to equip users with the knowledge needed to achieve professional results in automotive, industrial, and creative projects.

What Is Silver Aerosol Spray Paint?

I’ve learned that silver aerosol spray paint is a type of paint that comes in a pressurized can and sprays out as a fine mist, giving surfaces a shiny, metallic silver look. I find it fascinating that it’s made up of pigments, solvents, and propellants, with the silver color usually coming from metallic particles. I use it a lot for quick projects because it’s so easy to apply and works on all kinds of surfaces. It’s especially popular for things like car touch-ups, DIY crafts, and even art because it dries fast and leaves a smooth, glossy finish. However, I always make sure to use it in a well-ventilated space since it has volatile organic compounds (VOCs) and can be flammable, so safety is key.

Looking into its background, I discovered that aerosol spray paint was first invented in the 1940s, originally for military and industrial stuff. It wasn’t long before it became available for everyday use, and silver became one of the go-to colors. Over time, I’ve noticed that the formulas have gotten better—more durable, stickier, and even a bit greener with less harmful chemicals. Nowadays, I see silver aerosol spray paint everywhere, from workshops to homes, because it’s so handy and versatile. It’s pretty cool to think how something so simple has become such a big deal in so many areas.

Ingredients: Key Components of Silver Aerosol Spray Paint Aerosol

After researching several top-selling silver aerosol spray paint products and analyzing their ingredients, I’ve identified the common key components that make them work so well. The eye-catching silver shine comes from pigments like aluminum flakes or mica particles, which reflect light to produce that metallic effect I love seeing on finished projects. These pigments are mixed into a binder, usually an acrylic or alkyd resin, which I think of as the glue that sticks the pigment to the surface once the paint dries. To keep the mixture liquid and ready to spray, solvents such as toluene or xylene are added—they evaporate fast, which is why the paint dries so quickly after I use it. The spraying action itself is powered by propellants, typically gases like propane or butane, compressed inside the can to push the paint out when I press the nozzle. Lastly, there are additives that I’ve found enhance the paint’s performance: anti-settling agents stop the pigments from sinking to the bottom, and UV stabilizers keep that silver shine from fading under sunlight.

If you’re still unclear about the ingredients above or want to customize your own silver aerosol spray paint can, feel free to reach out to us. We specialize in producing silver aerosol spray paint cans and offer finished product filling services too. Contact us today!

Technical Specifications and Performance

Silver aerosol spray paint, like the European Aerosol RAL 9006 (White Aluminum), offers impressive performance metrics:

Coverage: ~0.8-1.0 m² per 400ml can, depending on surface and application.

Drying Time (20°C, 50% humidity): Dust-free in 10 minutes, touch-dry in 30 minutes.

Gloss Level: Satin (30 gloss units at 60° angle, per DIN 67530).

Temperature Resistance: Up to 90°C.

Storage Stability: Up to 10 years in cool, dry conditions (10-25°C, ≤60% humidity).

VOC Content: ~238.1 g/L, requiring careful handling due to environmental impact.

These specs make it a reliable choice for both quick touch-ups and professional-grade projects.

How to Use Silver Aerosol Spray Paint Safely and Effectively

To achieve flawless results while staying safe, follow these expert tips:

Prepare the Surface: Clean and dry the surface using a degreaser (e.g., ColorMatic silicone remover) to remove dirt or oils.

Shake Well: Shake the can for 2 minutes to mix pigments evenly.

Apply Thin Layers: Spray 2-3 light coats, holding the can 20-30 cm from the surface, with 5-minute intervals between coats.

Ventilation is Key: Work in a well-ventilated area to avoid inhaling harmful VOCs (e.g., toluene exposure limit: 191 mg/m³ over 8 hours).

Wear PPE: Use gloves, safety glasses, and a mask or respirator, especially in confined spaces.

Store Safely: Keep cans away from heat sources and sunlight to prevent explosions (flash point: -4°C).

Eco-Friendly Disposal: Avoid puncturing or burning cans. Empty cans completely before recycling per local regulations.

Pro Tip: Test the paint on a small area to ensure color accuracy, especially for automotive or art projects.

Safety and Environmental Considerations

Silver aerosol spray paint is highly flammable (flammability range: 3.4-26.7%) and contains chemicals like dimethyl ether and zinc powder, which can irritate skin or harm aquatic ecosystems. According to the Dulux METALSHIELD SDS, it’s classified as a dangerous good for transport and requires careful handling. To minimize risks:

Avoid spraying near open flames or sparks.

Store in a cool, dry place (10-25°C).

Prevent runoff into water sources to protect aquatic life.

Follow the product’s SDS for brand-specific safety guidelines.

Why Silver Aerosol Spray Paint is a Game-Changer

Silver aerosol spray paint combines convenience, durability, and a dazzling metallic finish, making it a favorite for countless applications. From transforming old furniture to protecting steel from corrosion, its quick-drying formula and high coverage save time and effort. With top brands like Montana, Krylon, and Rust-Oleum leading the way, there’s a silver spray paint for every project and budget.

Ready to start your next project or create custom silver aerosol spray paint cans? Contact us today for expert production and filling services.

Top 5 Silver Aerosol Spray Paint Brands

After researching brand reputation, product quality, and consumer feedback, I’ve ranked the top five silver aerosol spray paint brands for their vibrant finishes and versatility across art, DIY, and industrial projects.

- Montana: Renowned in the art world, Montana’s GOLD Metallic Silver Matt offers a durable, matte silver finish. Its low-pressure system ensures precision, ideal for canvas, wood, and metal. Consumers praise its rich tone and weather resistance.

- MTN (Montana Colors): Popular for graffiti, MTN Liquid Metallic Silver delivers a glossy, UV-resistant finish. It suits wood, glass, and resin art, with high opacity and scratch resistance, earning strong reviews for versatility.

- Krylon: Known for accessibility, Krylon Metallic Silver provides a shiny, mirror-like finish. It’s fast-drying, covers wood, metal, and plastic well, and is a favorite for DIY projects due to its smooth application.

- Rust-Oleum: Rust-Oleum Specialty Silver Metallic uses real metallic flakes for a durable, corrosion-resistant finish. Ideal for automotive and heavy-use items, it’s praised for its elegant shine but needs sealing for outdoor use.

- Ironlak: A graffiti favorite, Ironlak Silver offers a glossy, high-pigment finish. Eco-friendly with low acetone, it’s durable on multiple surfaces and valued for affordability and vibrant results.

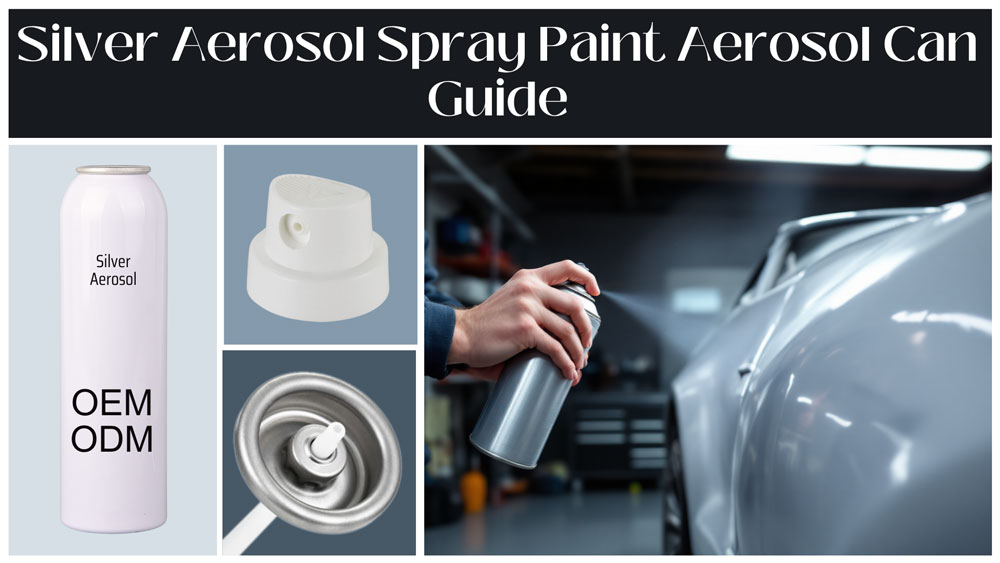

Silver Aerosol Spray Paint Services

This article explores the fundamentals of silver aerosol spray paint. As a leading manufacturer of aluminum aerosol cans, we produce high-quality empty cans ranging from 30ml to 800ml, complete with a comprehensive set of valves and actuators. Need your cans filled? We offer professional OEM filling services, using either our proven formulas or custom formulations tailored to your specifications.

With 35 years of expertise in aluminum can manufacturing, we ensure a reliable 30-day delivery period for our products. For customers in the American market, our cans meet US DOT 2P and 2Q certification standards. Contact us today to discover more about our silver aerosol spray paint packaging solutions and how we can meet your needs!