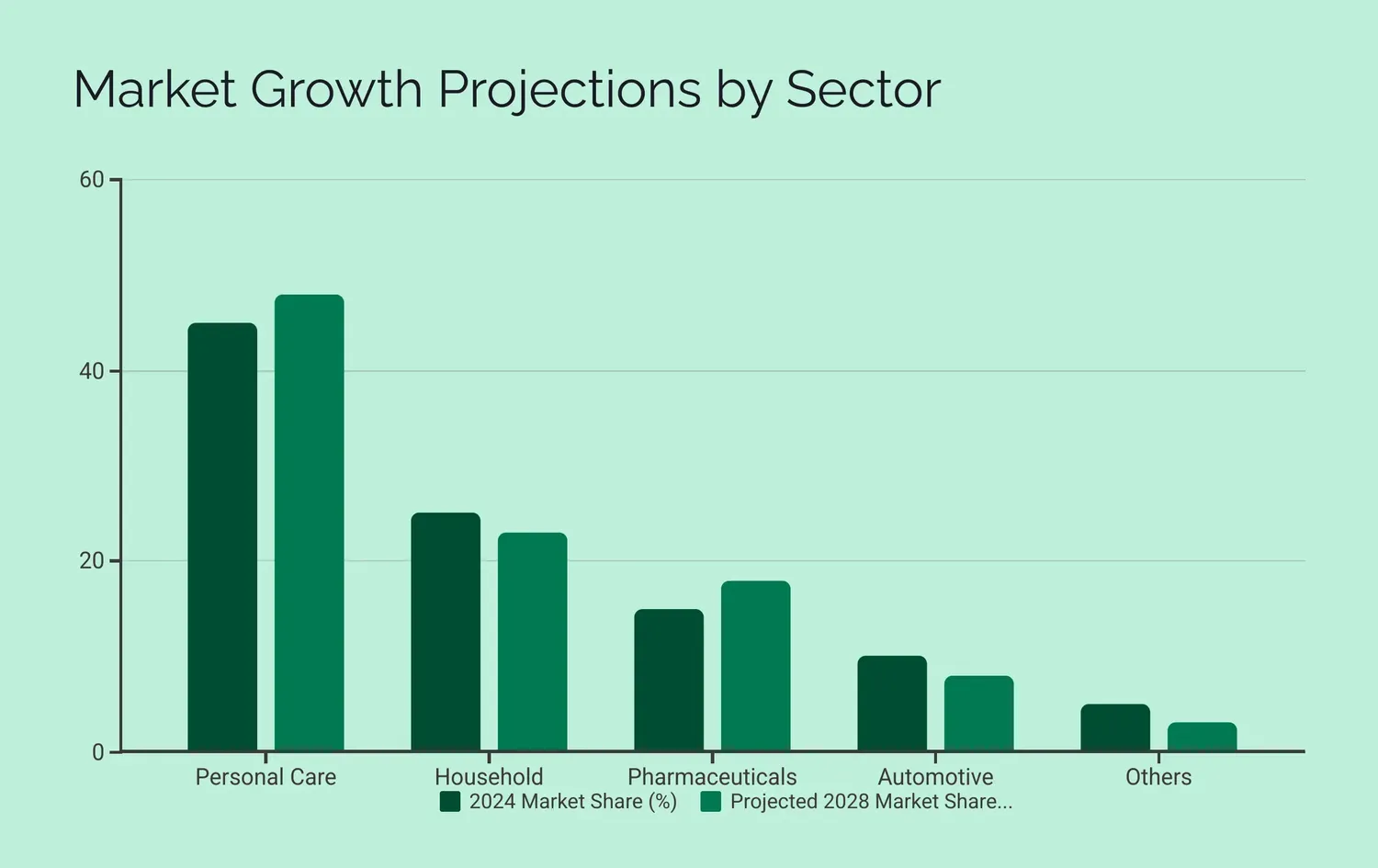

The Australian aerosol can market is thriving in 2024, propelled by rising demand in personal care, pharmaceuticals, and household products, alongside a strong push for sustainable packaging. With a market size of approximately $1.04 billion and a projected CAGR of 5% through 2028, Australia presents significant opportunities for B2B partners seeking innovative and eco-friendly packaging solutions. This article explores the market’s potential, the advantages of aluminum aerosol cans, and emerging industry trends shaping the future.

Growing Demand in the Australian Aerosol Can Market

In 2024, the Australian aerosol can market is driven by robust demand in key sectors. The personal care segment, including hairsprays, deodorants, and dry shampoos, remains the largest, fueled by Australia’s $22 billion beauty and cosmetics industry. Pharmaceuticals, particularly metered-dose inhalers (MDIs), also contribute significantly, supported by steady healthcare investments. Household products like air fresheners and insecticides maintain stable demand, while the automotive and construction sectors boost the need for paints and lubricants.

Australia’s appeal as a market lies in its commitment to sustainability and high-quality standards. Consumers increasingly favor eco-friendly products, aligning with global trends toward sustainable packaging. The country’s robust regulatory framework, including compliance with AS 2278.1 and updated workplace exposure standards, ensures product safety and environmental responsibility. Additionally, Australia’s growing e-commerce sector enhances accessibility, making it an ideal hub for innovative packaging solutions.

Why Aluminum Aerosol Cans Lead the Market

Aluminum aerosol cans are gaining traction in Australia due to their superior environmental and functional benefits. Unlike tinplate, aluminum offers exceptional recyclability, with up to 50% post-consumer recycled (PCR) or post-industrial recycled (PIR) aluminum used in modern cans, reducing carbon footprints. Their lightweight design lowers transportation costs and emissions, while advanced printing technologies enable vibrant, brand-enhancing designs that appeal to eco-conscious consumers.

Aluminum’s corrosion resistance and excellent barrier properties make it ideal for sensitive products like pharmaceuticals and personal care formulations. Companies leveraging PCR aluminum, such as those producing deodorant cans, demonstrate a commitment to circular economy principles, aligning with Australia’s sustainability goals. These advantages position aluminum aerosol cans as the preferred choice for brands seeking to meet both consumer and regulatory expectations.

Emerging Trends Shaping the Australian Aerosol Can Industry

The Australian aerosol can market is evolving rapidly, driven by technological advancements and shifting consumer preferences. Key trends include:

- Lightweight Cans: Manufacturers are adopting thinner aluminum walls to reduce material use without compromising durability, lowering costs and environmental impact.

- Eco-Friendly Propellants: Low-VOC and hydrocarbon-based propellants are replacing traditional options, meeting stricter environmental regulations.

- Smart Valve Systems: Bag-on-valve (BOV) technology enhances product delivery precision, particularly for cosmetics and medical applications, improving user experience.

Category shifts are also notable. Personal care continues to dominate, driven by demand for natural and organic products, while automotive and industrial applications grow due to a 8.4% rise in construction activity in 2023. The shift toward aluminum over tinplate is accelerating, with aluminum’s market share rising as sustainability becomes a priority.

Aluminum vs. Tinplate: A Market Share Comparison

| Material | 2023 Market Share | 2024 Market Share |

|---|---|---|

| Tinplate (Steel) | 70% | 70% |

| Aluminum | 30% | 30% |

While tinplate still holds a 70% share, aluminum’s adoption is expected to grow as manufacturers invest in PCR aluminum and lightweight designs to meet sustainability demands.

Partnering with a Reliable Aluminum Aerosol Can Manufacturer

Shining, a trusted name in aluminum aerosol can production, delivers high-quality, customizable solutions that meet ASI and EU standards. With extensive export experience and a focus on eco-friendly manufacturing, Shining offers lightweight, recyclable cans tailored to personal care, pharmaceutical, and household applications. Our commitment to innovation ensures compliance with Australia’s stringent regulations, making us a reliable partner for global brands seeking sustainable packaging. We look forward to collaborating with businesses to provide cutting-edge aluminum aerosol can solutions that drive success in the Australian market.

Conclusion

The 2024 Australian aerosol can market offers immense potential, driven by demand in personal care, pharmaceuticals, and automotive sectors, alongside a strong focus on sustainable packaging. Aluminum aerosol cans, with their recyclability, lightweight design, and aesthetic appeal, are at the forefront of this growth. As trends like eco-friendly propellants and smart valves gain traction, partnering with a professional manufacturer ensures access to innovative, compliant solutions. Australia’s dynamic market is ready for brands to seize these opportunities.